Introduction

Thermoforming machines are integral to various manufacturing processes, providing efficient and versatile solutions for creating plastic products. These machines are not just tools for industry, they also help create everyday items and advanced components. In this article, we will explore ten surprising facts about thermoforming machines, including their abilities, uses, and advancements.

What is Thermoforming?

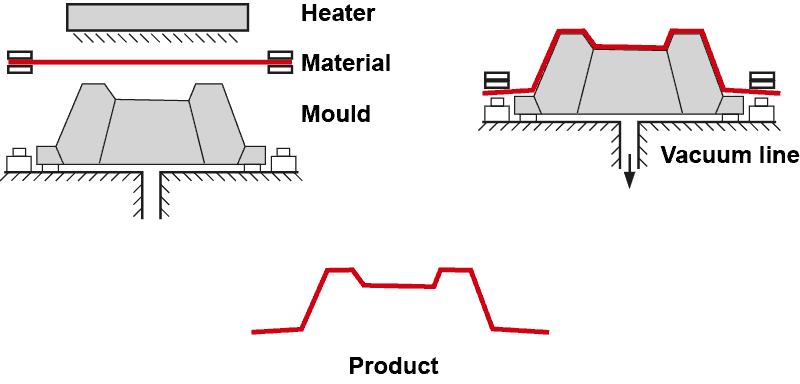

Thermoforming shapes a heated plastic sheet in a mold and cuts it to make a product. Many industries commonly use this process for packaging, automotive parts, and many other applications.

The Evolution of Thermoforming Machines

Early Beginnings

Thermoforming technology started in the early 1900s with basic tools and manual work. It has since advanced with better machinery and automation.

Modern Advancements

Today, thermoforming machines are highly sophisticated, utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) to achieve precise and efficient production.

Versatility in Applications

Different industries use thermoforming machines to produce various items. These items include food packaging, medical devices, car parts, and consumer products. The machines have the capability to make both large and small items with intricate designs. These machines can create both large-scale and small-scale items with intricate designs.

Environmental Benefits

Recycling Capabilities

Thermoforming is an environmentally friendly process. Manufacturers can make the plastic sheets from recycled materials and typically reuse any leftover scrap during manufacturing.

Energy Efficiency

Designers have made modern thermoforming machines energy-efficient to reduce the overall carbon footprint of the manufacturing process.

High Precision and Consistency

Thermoforming machines offer high precision and consistency, which is critical for industries requiring exact specifications. Advanced control systems and automation achieve this precision, ensuring each product meets stringent quality standards.

Cost-Effective Production

Thermoforming is a cost-effective manufacturing method, particularly for producing large volumes of items. The initial setup costs are relatively low, and the process allows for rapid production, reducing labor costs.

Customization and Flexibility

Design Flexibility

Thermoforming machines offer great flexibility in design. Manufacturers can quickly change molds to make different products, which is great for custom manufacturing.

Prototyping and Low-Volume Production

These machines are excellent for testing new designs and ideas without spending a lot of money. They are ideal for prototyping. You can learn more about low-volume manufacturing here.

Speed and Efficiency

Thermoforming machines are known for their speed and efficiency. The process can produce a high volume of products in a short amount of time, which is essential for meeting market demands and deadlines.

Technological Integration

Automation

Many modern thermoforming machines incorporate automation to streamline the production process. Automated systems handle tasks such as material loading, forming, trimming, and unloading, increasing efficiency and reducing human error.

Smart Manufacturing

With the rise of Industry 4.0, thermoforming machines are becoming smarter. Connecting to IoT enables monitoring and analyzing data in real-time, improving performance and maintenance schedules.

Diverse Material Compatibility

Thermoforming machines can work with many materials, such as PVC, PET, and polystyrene. This lets manufacturers pick the right material for their needs, considering cost, strength, and environmental impact.

Challenges and Solutions

Material Limitations

While thermoforming is versatile, it does have some material limitations. Some materials may require specific conditions for thermoforming because not all plastics can undergo the process.

Technological Solutions

Researchers and engineers always create new materials and machines to improve processes and provide more options for use. These advancements help make tasks easier and faster. They also allow for more creativity and innovation in various industries. Overall, the continuous development of materials and machines benefits society by improving efficiency and expanding possibilities.

FAQs

How does thermoforming differ from injection molding?

Thermoforming heats a plastic sheet and shapes it with a mold, while injection molding uses molten plastic in a mold. Thermoforming is generally more cost-effective for large parts and low-volume production.

What are the main types of thermoforming machines?

The main types are vacuum forming and pressure forming machines. Vacuum forming pulls plastic sheet against mold with vacuum, while pressure forming uses air pressure for more detailed shapes.

Can thermoforming machines handle biodegradable plastics?

Yes, thermoforming machines can process biodegradable plastics. This is becoming increasingly important as industries move towards more sustainable practices.

What industries benefit the most from thermoforming?

Industries such as packaging, automotive, medical, and consumer goods benefit significantly from thermoforming due to its versatility, precision, and cost-effectiveness.

How long does it take to produce a thermoformed product?

Thermoforming is usually a quick process, but the production time may change based on the product’s complexity and size. High-speed machines can produce thousands of items per hour.

Is thermoforming suitable for high-volume production?

Yes, thermoforming is well-suited for high-volume production. Its efficiency and speed make it ideal for producing large quantities of items quickly and cost-effectively.

Conclusion

Thermoforming machines are important in manufacturing because they are versatile, cost-effective, and efficient for making different products. These machines have evolved over time to become advanced systems, revolutionizing the production of everyday items.

Thermoforming provides numerous benefits for innovation and sustainability in industries such as packaging, automotive, and medical. These machines have come a long way from their early days to today’s advanced systems, changing the way we make everyday items. Whether you work in packaging, automotive, or medical industries, thermoforming offers many benefits for innovation and sustainability.

For more information on how thermoforming can benefit your manufacturing process, visit ProtoTech Machining. Ready to take the next step? Get a quote today!