Vacuum Casting

Urethane Vacuum Casting: ProtoTech Machining, on the leading edge of vacuum casting technology, can create silicone rubber molds producing urethane cast parts quickly and accurately.

- Save 30% on average

Vacuum Casting Materials

Polypropylene (PP) like (80D)

Ultimaker PP (polypropylene) is a durable, chemical resistant material. It has exceptional fatigue resistance, high levels of toughness, and a low-friction co-efficient.

Colors: All colors; precise pantone color matching available

Hardness: Shore D 78-82

Applications: General purpose items, enclosures

Polycarbonate (PC) like (75D)

Stiff, transparent urethane resin simulating acrylic. It is hard, with medium to high strength and good clarity for see-through products.

Colors: Clear

Hardness: Shore D 87

Applications: Light pipes, see-through components

Acrylonitrile Butadiene Styrene (ABS) like (83D)

Tough, flexible, and abrasion-resistant urethane with low cost and polypropylene-like ductility.

Colors: Black or natural only

Hardness: Shore D 65-75

Applications: Enclosures, food containers, medical applications, toys

PE-like (65D)

Rigid, high-impact, and clear material with a wide variety of uses. Easy to machine and finish, simulating polycarbonate.

Colors: Clear and various colors

Hardness: Shore D 82-86

Applications: Light diffusers, signs, skylights, visors

Glass-Filled Nylon like

UV stable, high-quality urethane resin with good clarity. Great for glossy, clear parts as a classic substitute for acrylic-like.

Colors: RAL/Pantone colors

Hardness: Shore D 90-99

Applications: Lighting, signal display, partition material

Thermoplastic Polyurethane (TPU) like

High impact strength, low-cost resin with a wide range of options.

Colors: Pantone colors

Hardness: Shore D 85-90

Applications: Displays, disposable items, packaging

Polyamide (PA) like (80D)

Polyurethane plastic resin, simulating rubber-like materials like TPU, TPE and silicone rubber.

Colors: All colors and precise Pantone color matchings

Hardness: Shore A 20 to 90

Applications: Wearables, overmolds, gaskets

Polyurethane (PUR or PU) like

(25A, 30A 40A, 50A, 60A, 70A, 80A, 84D, 85A, 90A)

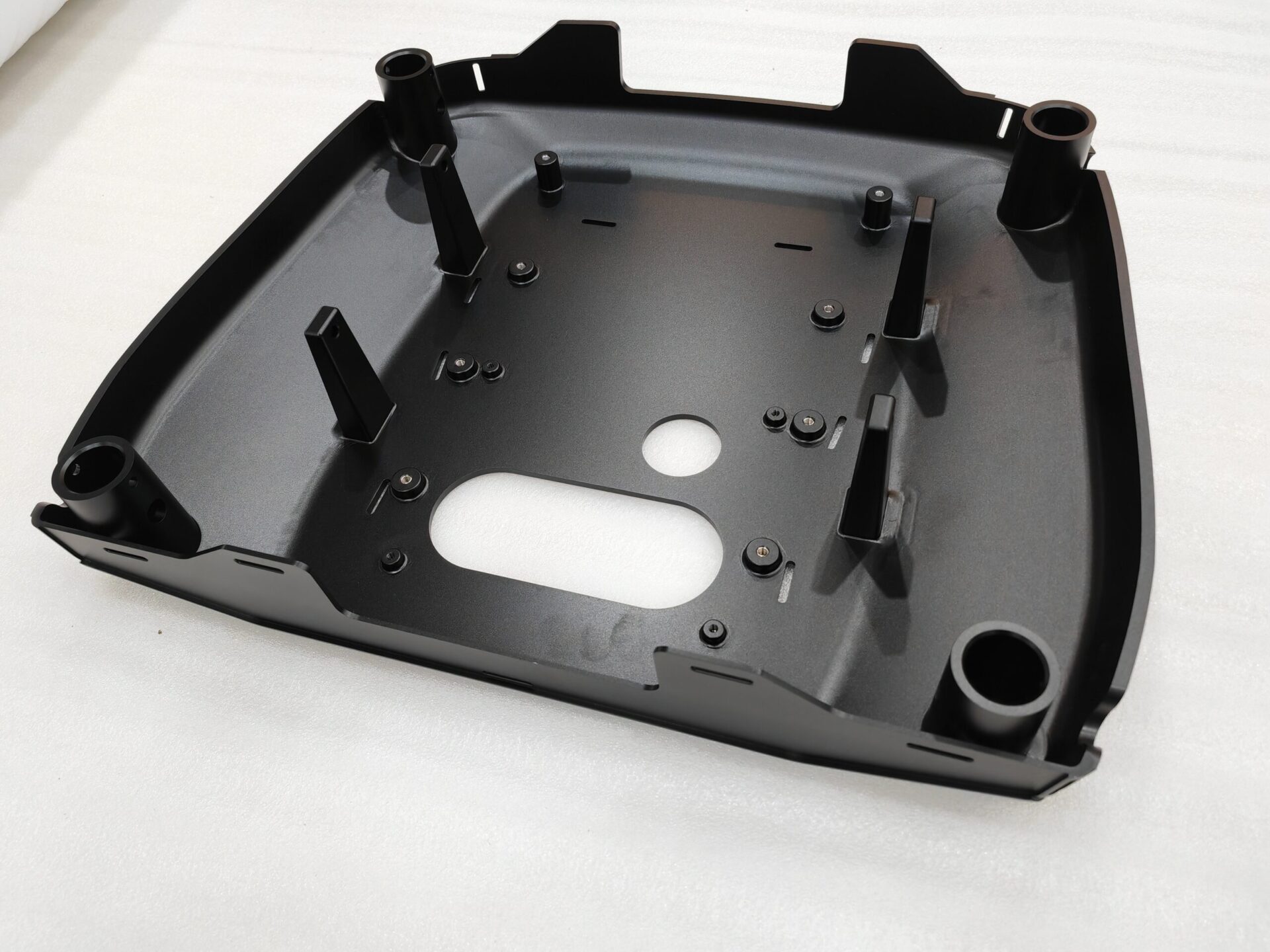

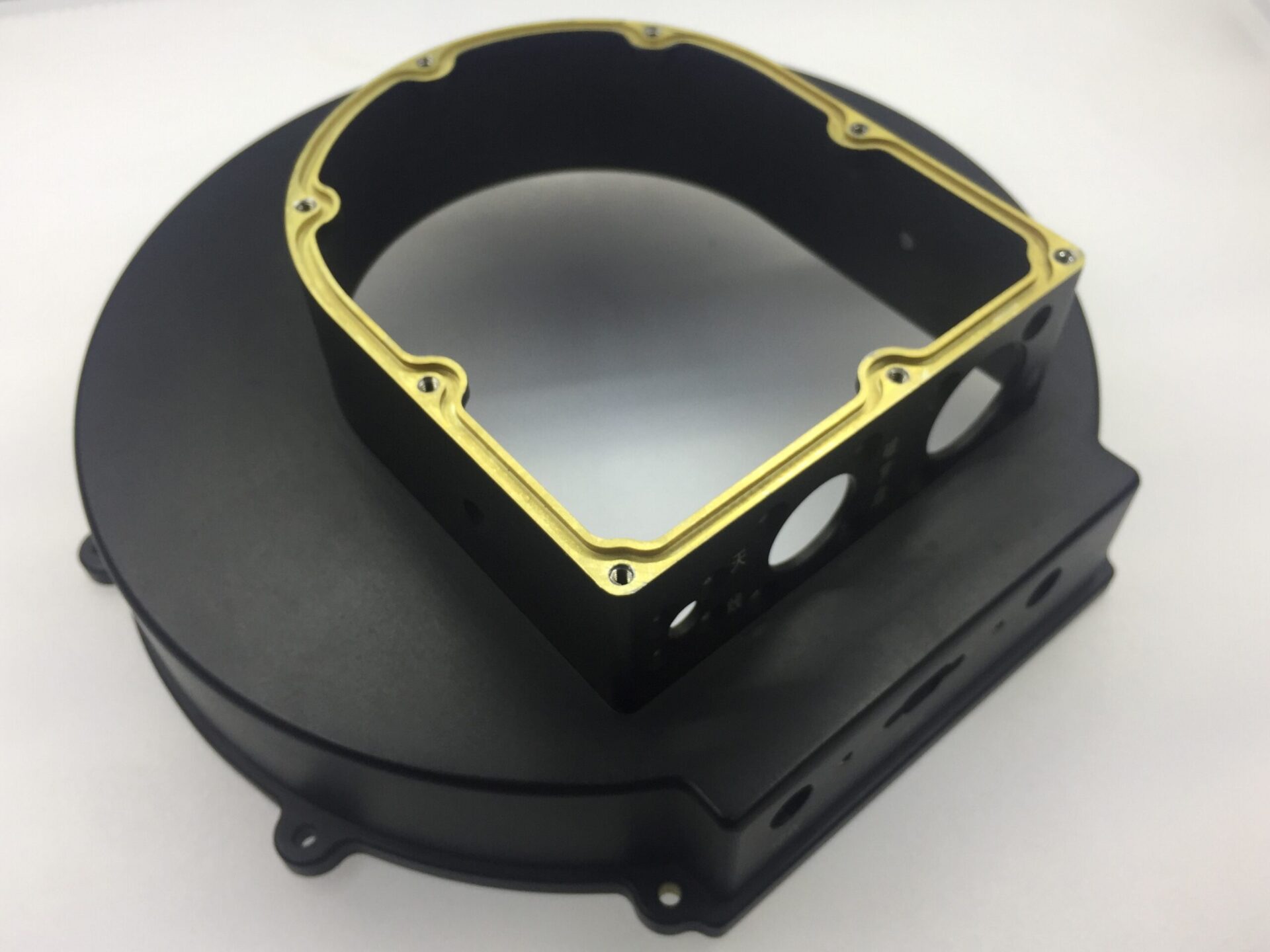

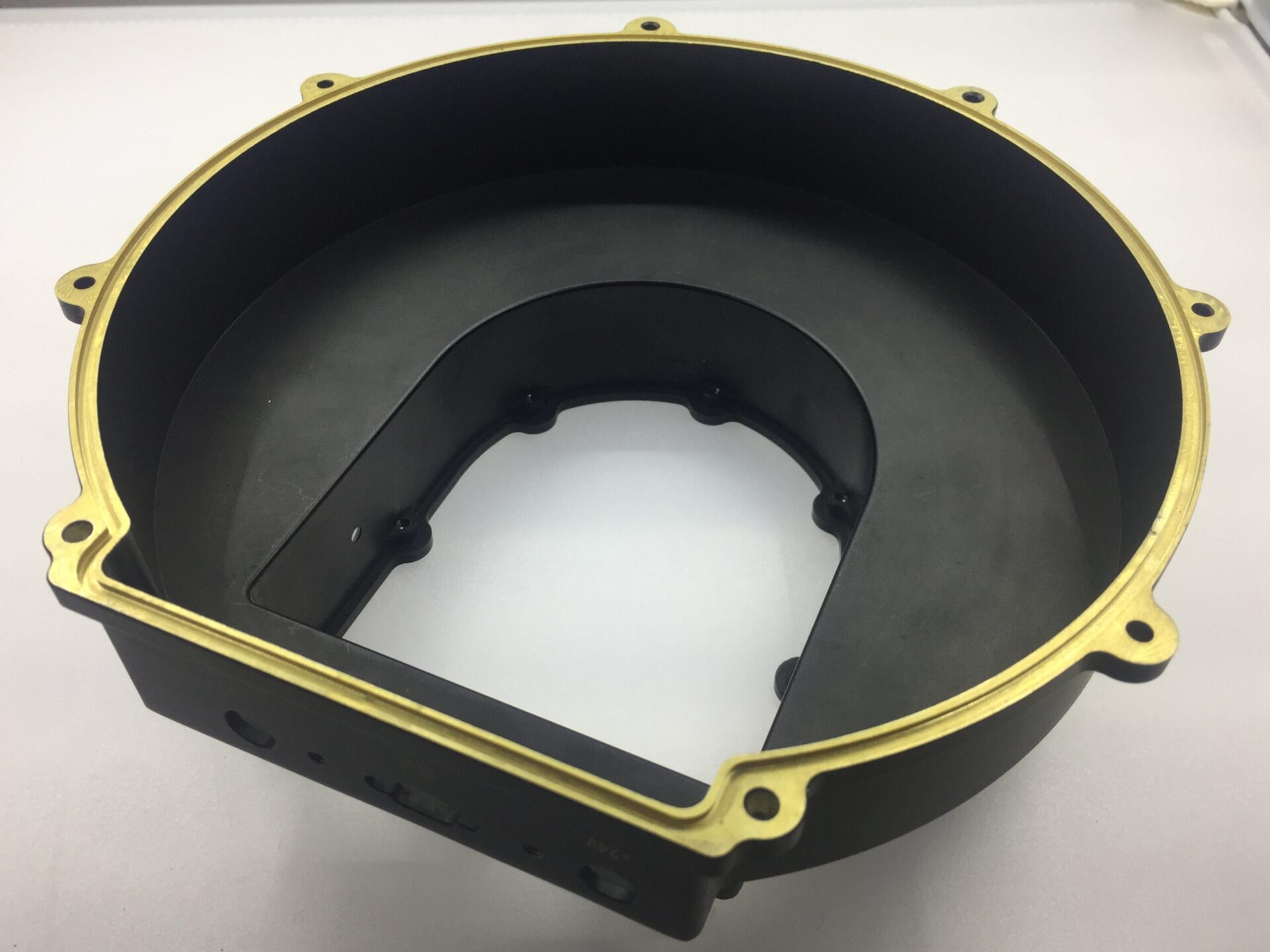

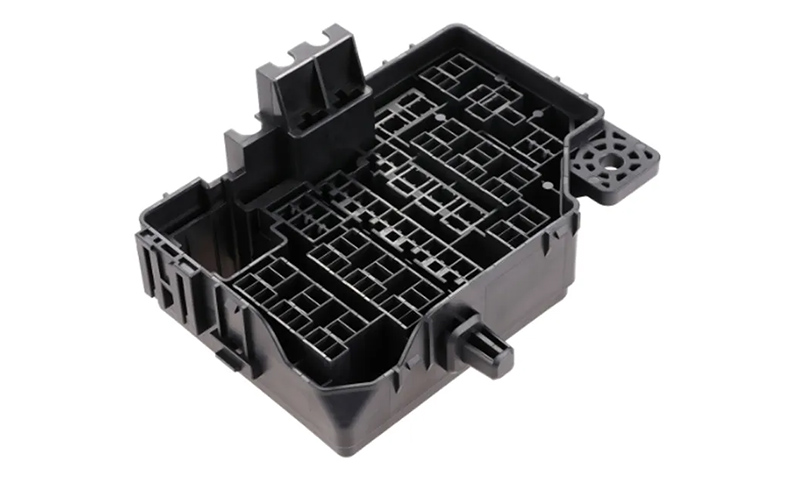

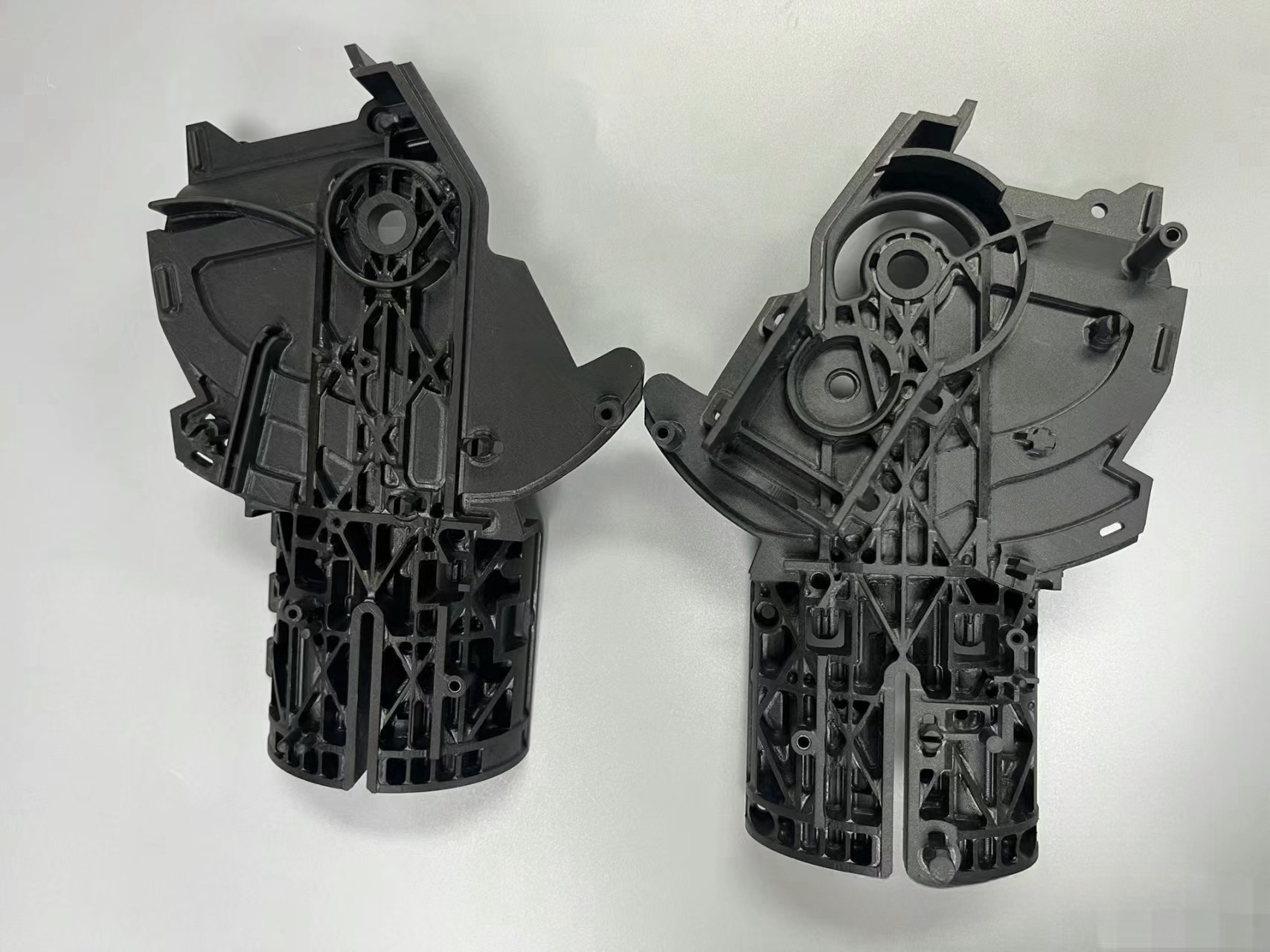

Gallery of Vacuum Casting Parts

We have been helping various industries such as aerospace, automotive, medical devices and other industries to develop various elastomeric vacuum cast parts for 20 years.

Surface Finish for Vacuum Casted Parts

With an extensive array of surface finishes, ProtoTech Machining can create unique surface layers for your vacuum casting parts. These finishes help you meet your products’ appearance, hardness, and chemical resistance requirements. Depending on your material selection and part applications, we can offer the following surface finishes:

Full Glossy

Semi-Glossy

Matte Finish

Custom Texture

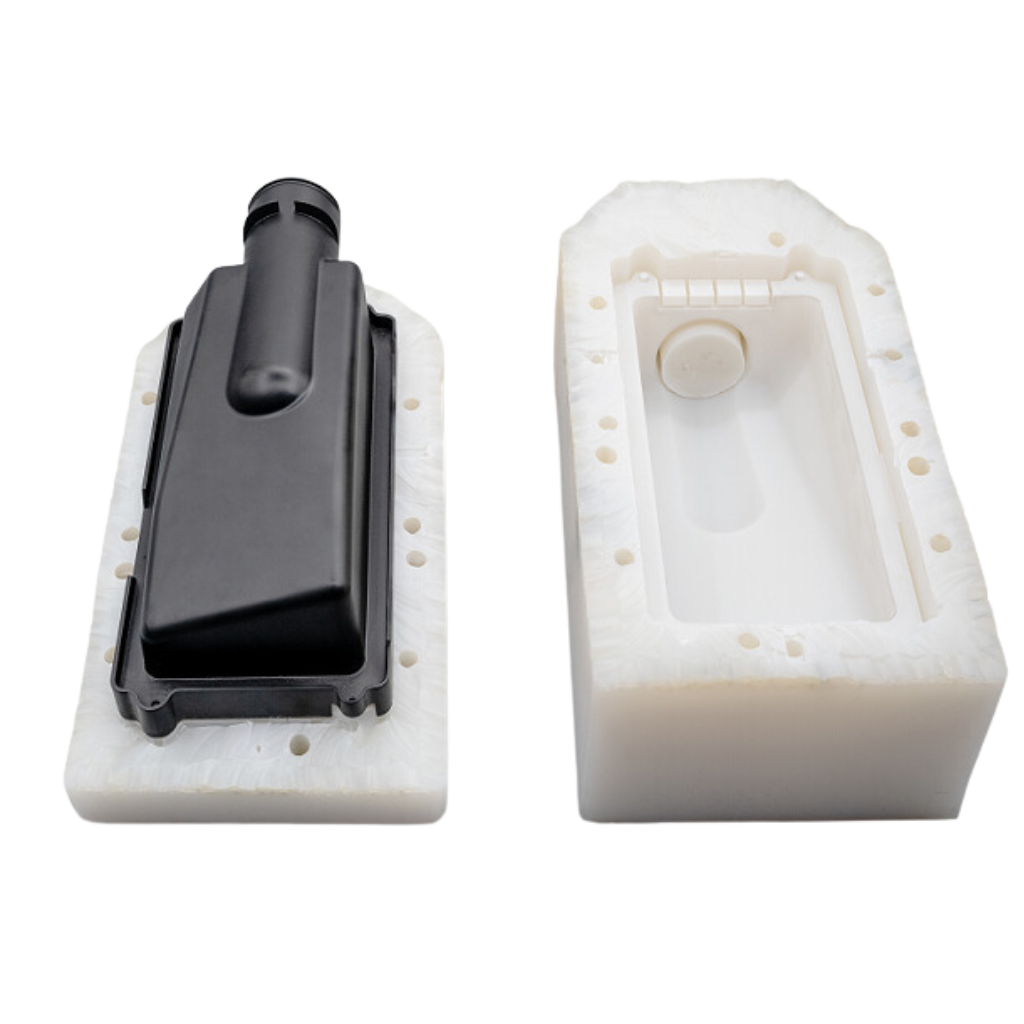

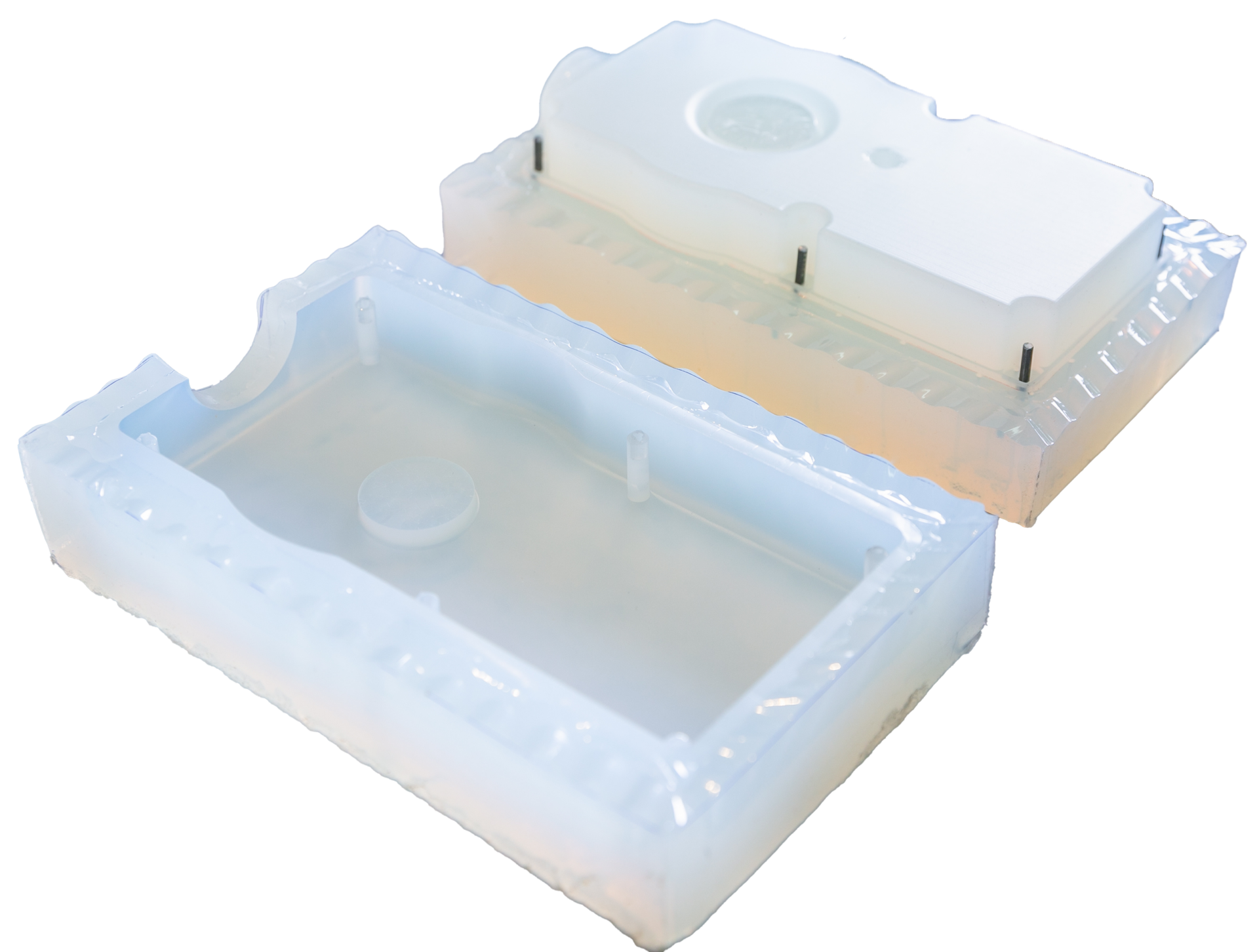

Silicone Rubber Mold Making

The master pattern serves as the basis for the creation of the silicone rubber mold, also referred to as an RTV mold, frequently used in urethane casting due to its chemical stability, self-releasing properties, and flexibility.

The lifespan of the silicone mold in prototype manufacturing is closely tied to the complexity of the casting part, generally producing 12-15 parts before deterioration. Simple designs allow for more output, possibly 20 parts from a single mold.

Steps to Creating a Silicone Rubber Mold

Polyurethane Casting Process Detail

Urethane casting at ProtoTech Machining effectively aligns with clients’ demands, whether it’s color, texture, glossiness, insert and over-molding, or even achieving optical clarity. Our standardized procedures assure precise part replication and uniform mechanical properties. Our experts control all operations: from mixing to de-molding, facilitating near-flawless replicas of the master pattern with a standard tolerance of ± 0.15mm/100mm and highest precision reaching ± 0.05 mm for prototype manufacturing.

Steps to Urethane Casting Process

Urethane casting matches client specifications, including color, texture, glossy finish, and clear features. The process involves placing a silicone mold in an oven, preheating polyurethane resins, mixing them in precise proportions, and degassing in a vacuum. The resin is poured into the mold under computer control, cured in the oven for 1-6 hours, and then the part is extracted from the mold.

Polyurethane Vacuum Casting Applications

Due to its fast production, low costs, and durable parts, our vacuum casting service is the favored option for making custom parts used in the automotive, medical, consumer goods, and other industries.

Low Volume Manufacturing / Short Production Runs