Automotive

Custom automotive prototyping and parts manufacturing services for automotive product development. Streamlined manufacturing processes, competitive prices, and on-demand production.

- Save 30% on average

Driving Innovation with ProtoTech Machining

Prototech Machining stands at the forefront of precision engineering solutions for the automotive industry, consistently delivering high-quality components that drive innovation and performance.

Automotive Prototyping and Production

The design process for automotive parts includes important steps such as CNC machining, rapid prototyping, and sheet metal fabrication. Prototypes are crucial for testing and improvement, and 3D printing technologies like FDM, SLS, and DMLS make the process faster and more cost-effective. Automotive engineers can also utilize Carbon Fiber Manufacturing and Aluminum Casting Molds for various applications. Injection Molding and Die Casting allow joining multiple components for large items. Online CNC machining and Vacuum Casting are options for low volume production. Sheet Metal Bending is used to create complex shapes and structures in the automotive industry.

What Materials Work Best for Automotive Applications?

Thermoplastics

Choose from hundreds of thermoplastics including PEEK, acetal, or opt for rapid prototyping with your own material. Preserve your branding by incorporating custom colorants for qualified projects.

Nylons

Utilize CNC machining and rapid prototyping to create functional prototypes, employing various nylon materials via selective laser sintering and Multi Jet Fusion. Enhance mechanical properties with mineral- and glass-filled nylons when required.

Aluminum

A versatile material for light-weighting, offers an outstanding strength-to-weight ratio and can undergo machining or 3D printing. Our services encompass CNC machining, rapid prototyping, sheet metal fabrication, injection molding.

What does ProtoTech Automotive Industry Offer?

Rapid Prototyping

Design reduces design risk by rapidly iterating and prototyping in production material without sacrificing development speed.

Supply chain flexibility

Get on-demand support for line emergencies, part recalls, or other supply chain disruptions in production plants by using automated quoting, rapid tooling, and low-volume production parts.

Quality inspection

Verify part geometry with a variety of quality documentation options. Digital inspection, PPAP and FAI reports available.

Mass Customization

Implement low-volume manufacturing to enable more diverse and customized automotive features that are tailored to modern drivers.

Tooling and Fixtures

Improve manufacturing processes to create greater automation and streamlined component assembly with custom fixturing.

Common automotive applications

Our digital manufacturing capabilities accelerate the development of a range of metal and plastic automotive components. A few of common automotive applications include:

- Assembly line components

- Fixtures

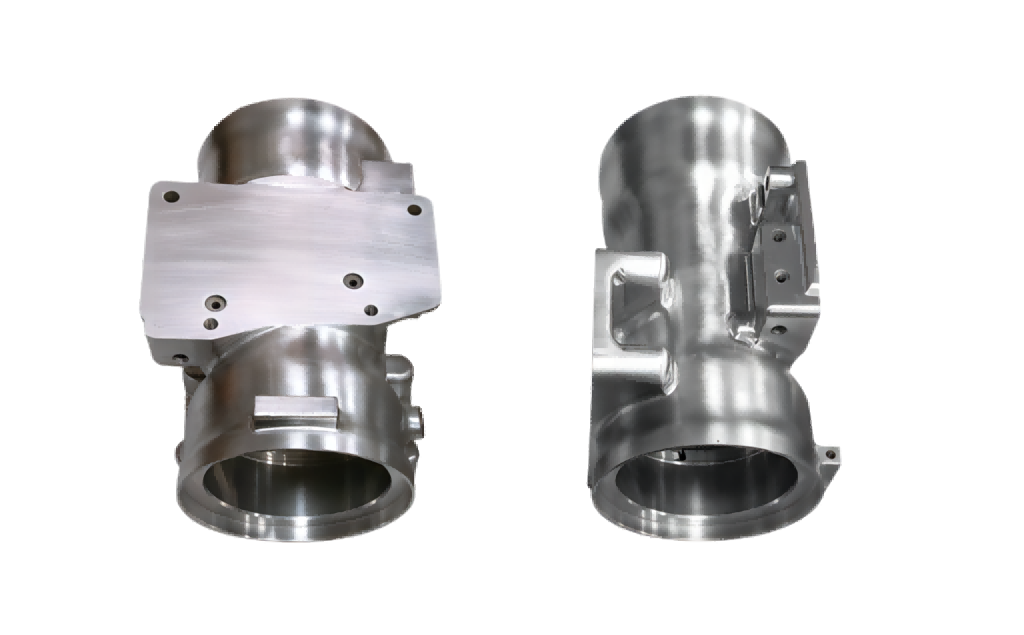

- Enclosures and housings

- Plastic dash components

- Aftermarket parts

- Armatures

- Lenses and lighting features

- Support for on-board consumer electronics

Examples of Automotive Rapid Manufacturing

ProtoTech Machining’s customers have used our rapid prototyping services and 3D printing/additive manufacturing capabilities to create a wide variety of parts, both large and small, in many different materials.