CNC Machining

CNC Prototype Machining: find the best fit CNC machining service for your plastic and metal parts. Produce and deliver parts on-demand.

- Save 30% on average

Services we offer at Prototech

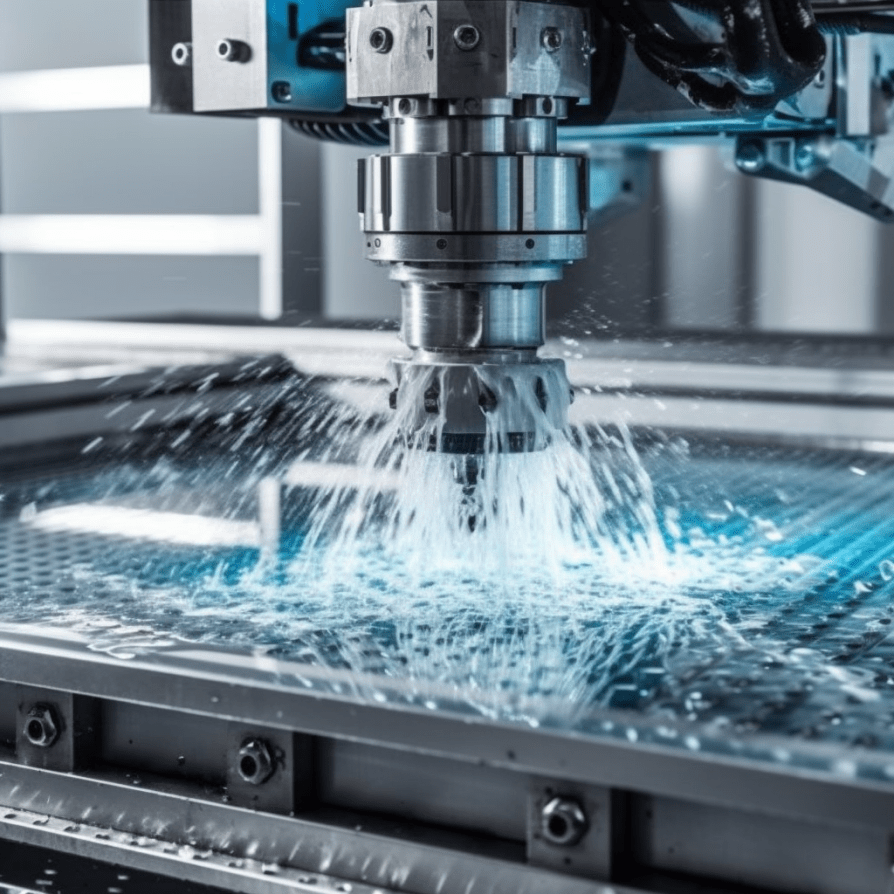

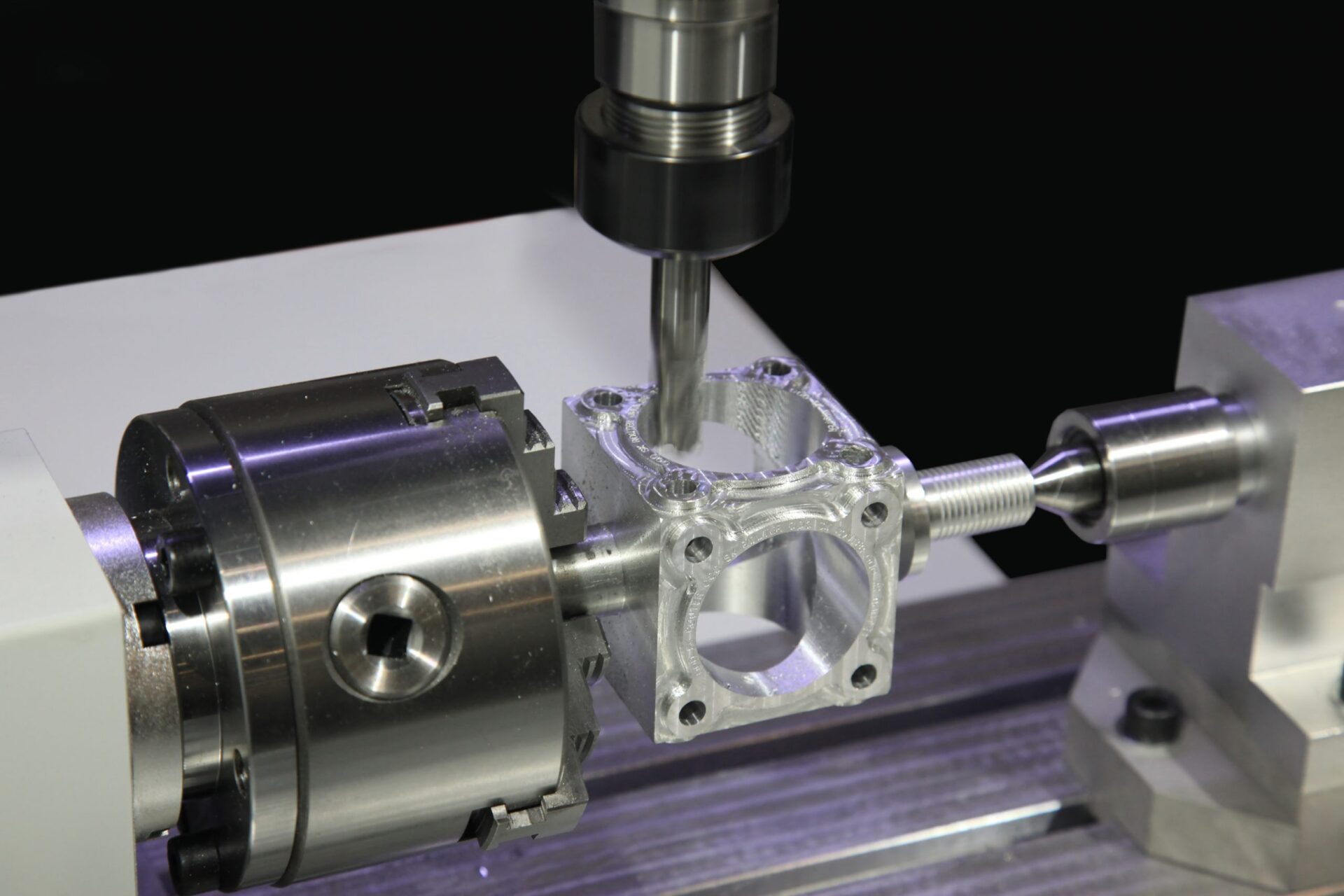

Milling

Up to 5-axis machining on HAAS UMC 1000 40”x25”x25” rotary table

Manual milling, drilling and tapping available

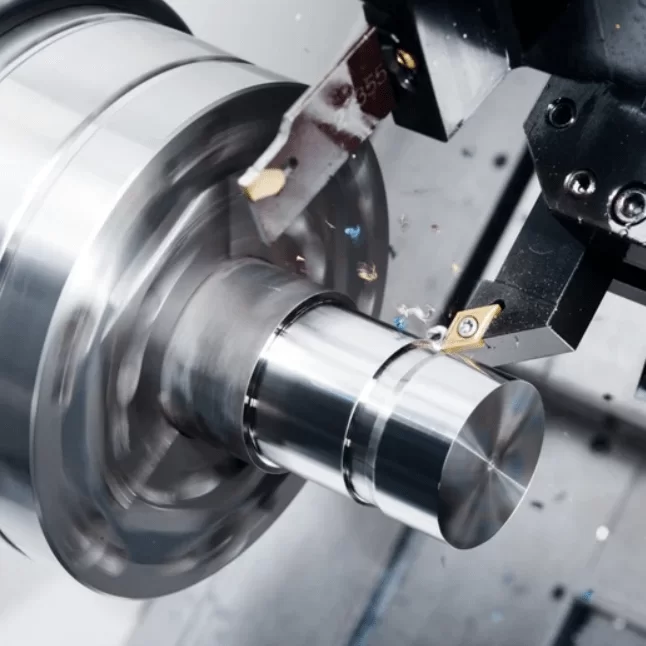

Turning

Rapid feed and live tooling

Up to 24″ deep bores with 6″ diameter

Manual turning availableUp to 30″ diameter by 80″ length with 25″ swing

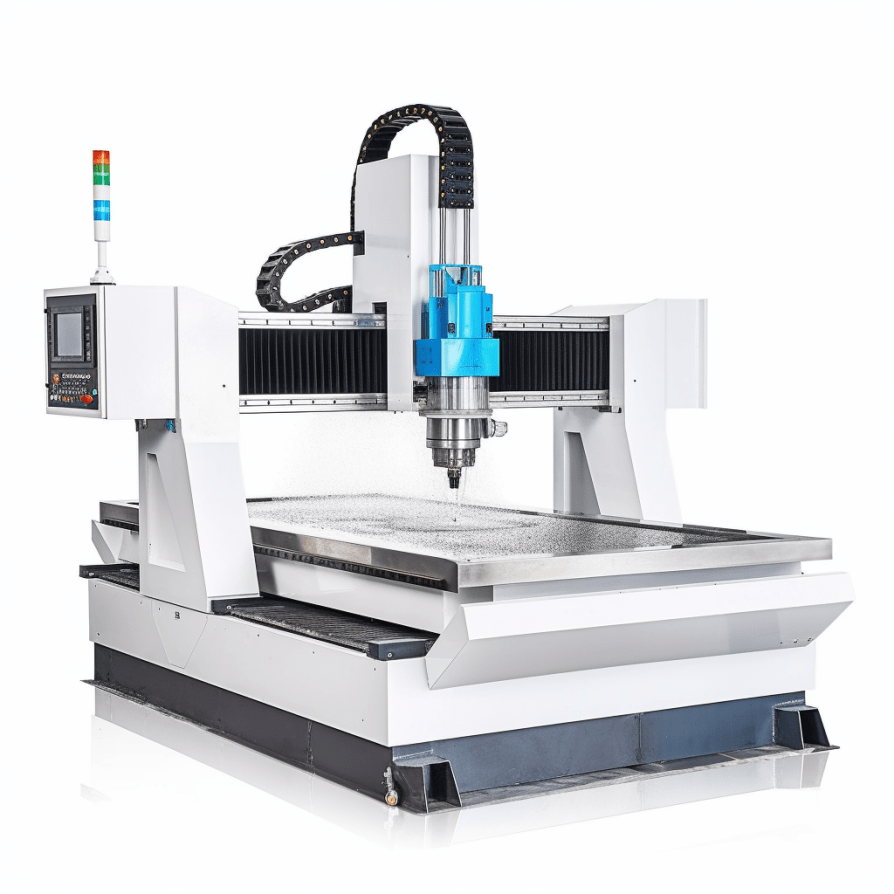

Routing

96″ x 48″ x 4″ working area

2D and 3D tool paths

Able to stack milled sections to produce large-scale pieces up to 48” tall

Materials For CNC Machining Parts

CNC Metals

Aluminum:Aluminium’s strength-to-weight ratio, economy and recyclability have led to its use in a wide range of industries worldwide.

Alloy:6061-T6、7075-T6、2024、5052、6060、5083、2017、6082

Surface Finish: Alodine, anodizing types II, III, III + PTFE, ENP, media blasting, nickel plating, powder coating, roller polishing

Stainless steel: Stainless steel’s corrosion resistance and ductility make it ideal for long-term exposure to elements and easy shaping into different forms

Finishing Options: As machined, Bead Blasted, Polishing, Decorative Chrome Plating, Powder Coat, Nickel Plating, Gold Plating, Silver Plating

Alloys: SS303, Stainless Steel 304/304L, Stainless Steel 316/316L, Stainless Steel 17-4, Stainless Steel 416, etc.

Alloy Steel: Alloy steel is steel mixed with elements like manganese, nickel, and chromium to enhance its strength, hardness, corrosion resistance, and durability, tailored to meet specific application needs.

Alloy: AISI 1215, AISI 4140, AISI 4340, AISI 8620, AISI 4130

Finishing Option: Polishing, Plating, Painting, Powder Coating and etc.

Tool Steel: Tool steel is a type of high-carbon and high-alloy steel that is specifically designed to be used in the manufacture of cutting tools, dies, and molds. It is valued for its high hardness, wear resistance, and toughness, which make it suitable for applications where the tool is subjected to repeated impacts or stresses.

Alloy: A2 Tool Steel, D2 Tool Steel, O1 Tool Steel, S7 Tool Steel, M2 Tool Steel

Finishing Option: Bead/Sand Blast, Polishing, Plating, Painting, Powder Coating, Heat Treatment and etc.

Brass: Brass is an alloy of copper and zinc, especially metal material with more than 20% zinc content, which is the most commonly used metal material in cnc machining

Finishing Options: Nickel Plating, Bead Blasted, Gold Plating, Silver Plating

Alloy: C360, C260, H59

Copper: Copper is a soft, malleable metal with excellent thermal and electrical conductivity, making it an essential material in many industries.

Grade: C10100, C11000, C12200, C14500, C17200

Finishing Option: Plating, Polishing

Titanium:Titanium has a low density and high strength, making it ideal for applications that require a strong yet lightweight material, such as aerospace, automotive, and biomedical industries. It is also highly resistant to corrosion and can withstand exposure to many chemicals and environments

Alloy: Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, Ti-3Al-2.5V

Finishing Option: Polishing, Anodizing, Sandblasting, Chemical etching, Laser engraving and etc.

Magnesium: Magnesium is a versatile and lightweight metal with a silvery-white appearance, known for its exceptional strength-to-weight ratio, excellent thermal and electrical conductivity, and widespread use in industries such as aerospace, automotive, and healthcare.

Alloy: AZ31B, AZ91D, We43, AM60B, ZK60A, QE22

Finishing Option: Blasting, Anodizing, Chromate Conversion Coating, Passivation, Powder Coating, Electroplating etc.

Kovar: Kovar is an Iron-Nickel-Cobalt alloy, best known for having a similar coefficient of thermal expansion (CTE) to Borosilicate glass and other optical materials that allows for glass-to-metal bonds.

Alloy: 4J33 4j29 4j364j294524J50 4J48 4J44 4J344J32 3j53

Finishing Option: Blasting, Plating, Chromate Conversion Coating, Electroplating etc.

Tungsten: chemical element that is an exceptionally strong metal

Alloy: YT5,YT14,YT15,YG6,YG6A,YG6X,YG8,YW1,YW2,YS8,YT726,YG643

Finishing Option: PVD, DLC, Hard chrome electroplate

CNC Plastics

POM (Delrin/Acetal): High stiffness, good moisture resistance, high wear-resistance, and low friction, easy to machine

Color: White, black, brown

Grade: POM-C, POM-H, UV stabilized POM, Food-Grade POM

PMMA: PMMA is commonly known by the trade name “acrylic” or “plexiglass”. It is a lightweight and shatter-resistant material that is often used as a glass substitute in applications such as skylights, displays, signage, and lenses

Color: Transparency

Grade: Extruded PMMA, Cast PMMA, Impact-Modified PMMA, UV-Stabilized PMMA, Heat-Resistant PMMA

PEEK: PEEK is a high-performance engineering thermoplastic with excellent mechanical, chemical, and thermal properties, short for Polyether Ether Ketone

Color: Beige with no transparency

Grade: Unfilled PEEK, 30% glass-fiber reinforced PEEK, 30% carbon-fiber-reinforced PEEK, Bearing Grade PEEK

ABS: ABS is tough, rigid, and lightweight, making it an excellent material for use in applications such as automotive parts, toys, electronic housings, and consumer goods. It is also resistant to impact, chemicals, and heat, making it a popular choice for use in harsh environments

Color: ABS is naturally opaque and comes in a range of colors including black, white, and gray

Grade: General purpose ABS, Flame retardant ABS, High impact ABS, Heat-resistant ABS

Nylon: Nylon is a strong, durable, and elastic material that is commonly used in textiles like clothing and ropes. Its resistance to abrasion, chemicals, and moisture makes it popular for industrial applications, such as gears, bearings, and automotive components

Color: Nylon is often used in its natural off-white or slightly yellowish color

Grade: Nylon 6, Nylon 6/6, Nylon 11, Nylon 12

PTFE: PTFE(Teflon) is a high-performance plastic material known for its exceptional chemical resistance, low friction coefficient, and high-temperature resistance

Color: The color of PTFE is typically white or off-white

Grade:

PVC: PVC stands for polyvinyl chloride, which is a synthetic thermoplastic polymer that is widely used in various applications. PVC is a versatile material that can be rigid or flexible

Color: clear or opaque

Grade: UPVC, PPVC, CPVC

PEI: PEI has excellent mechanical, thermal, and electrical properties, as well as good chemical resistance

Color: Amber or brownish color

Grade: Unfilled PEI, Glass-Filled PEI, Carbon-Filled PEI, Ultem PEI

PAI: or Torlon Polyamide-imide, is a type of thermoplastic polymer that is known for its excellent mechanical properties that it maintains over a wide range of temperatures.

Color: Yellow

Grade: Torlon4203, Torlon4503, Torlon4301,Torlon4501

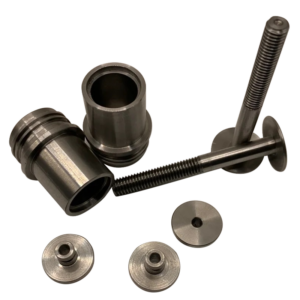

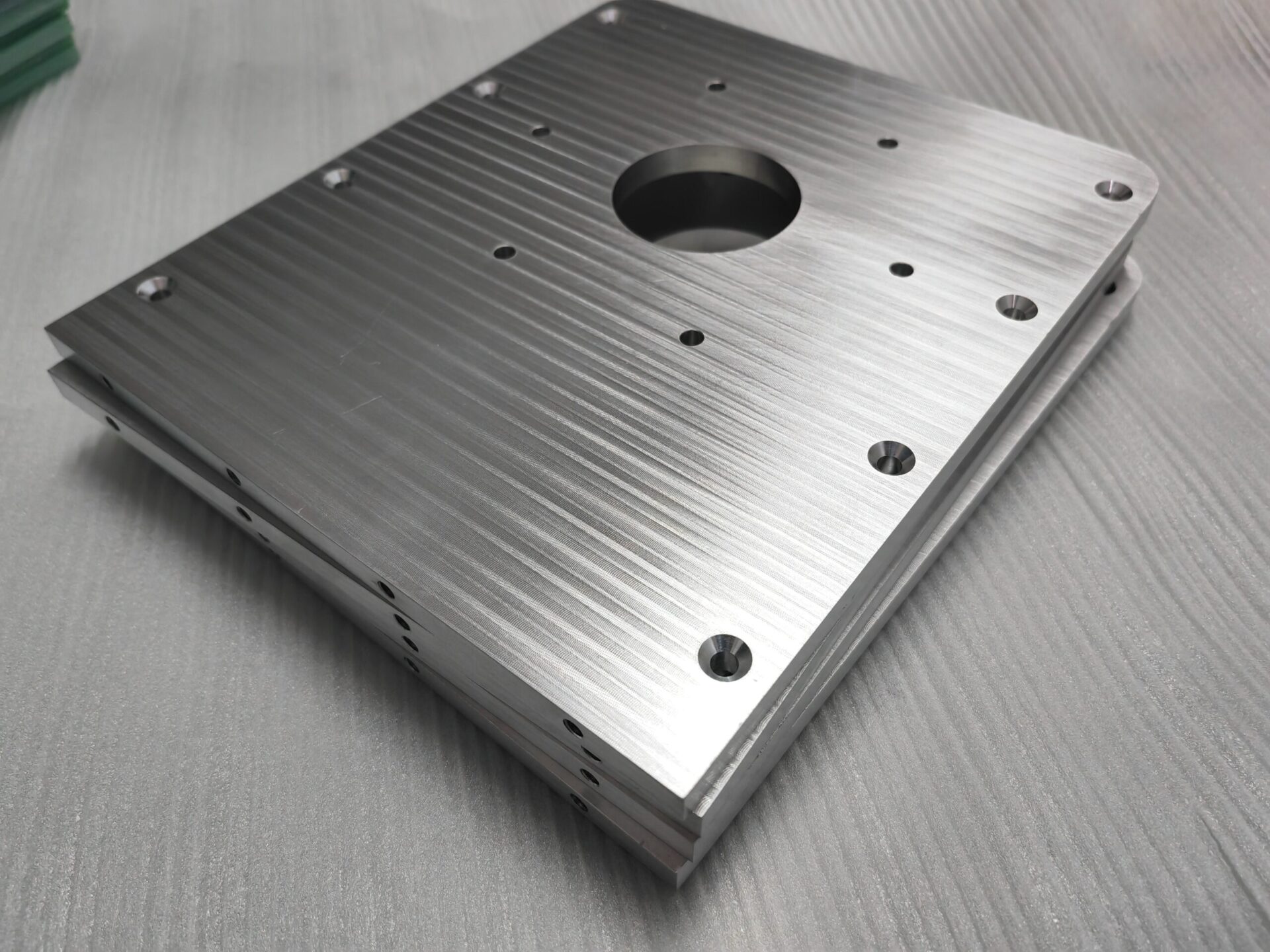

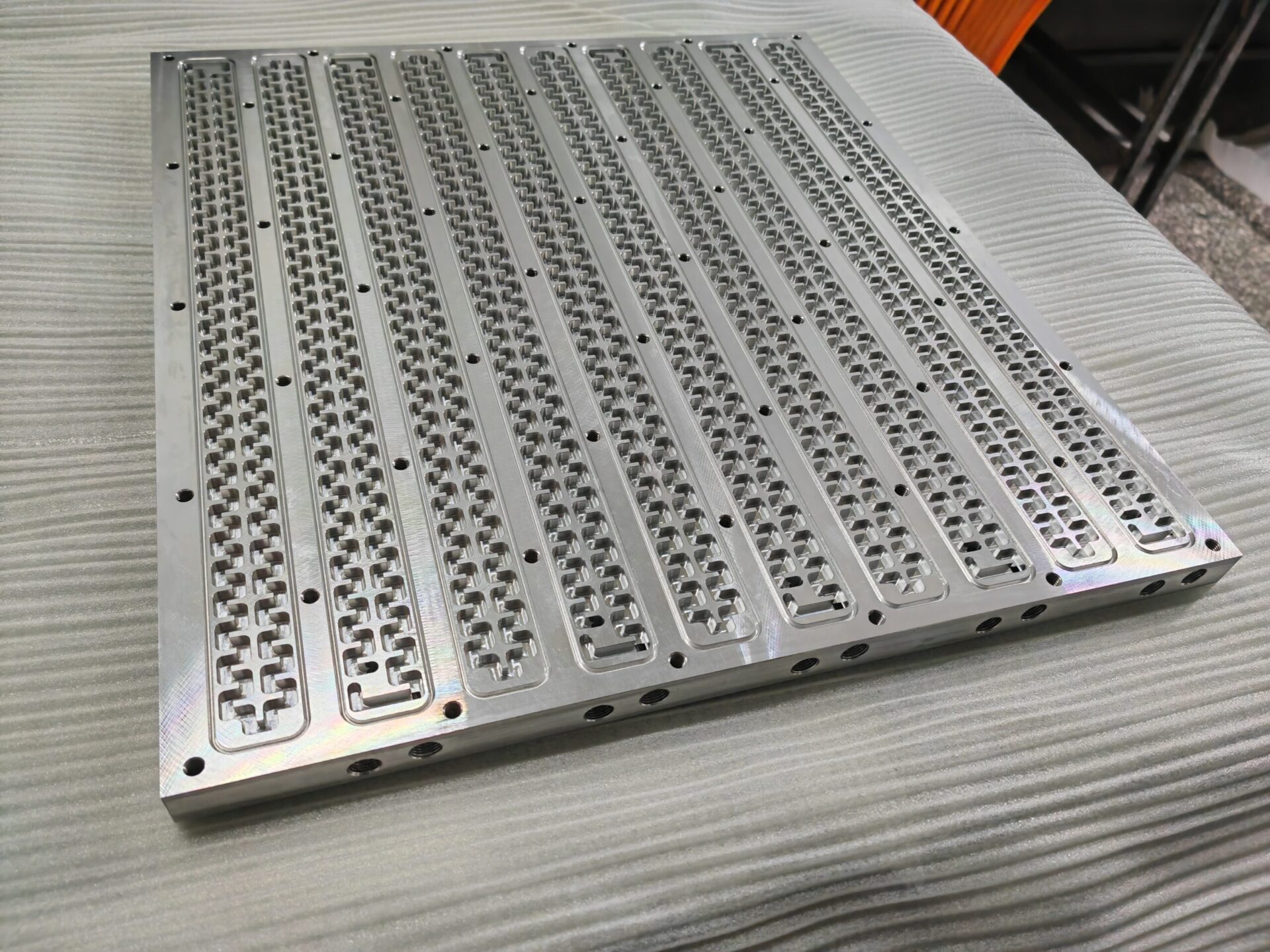

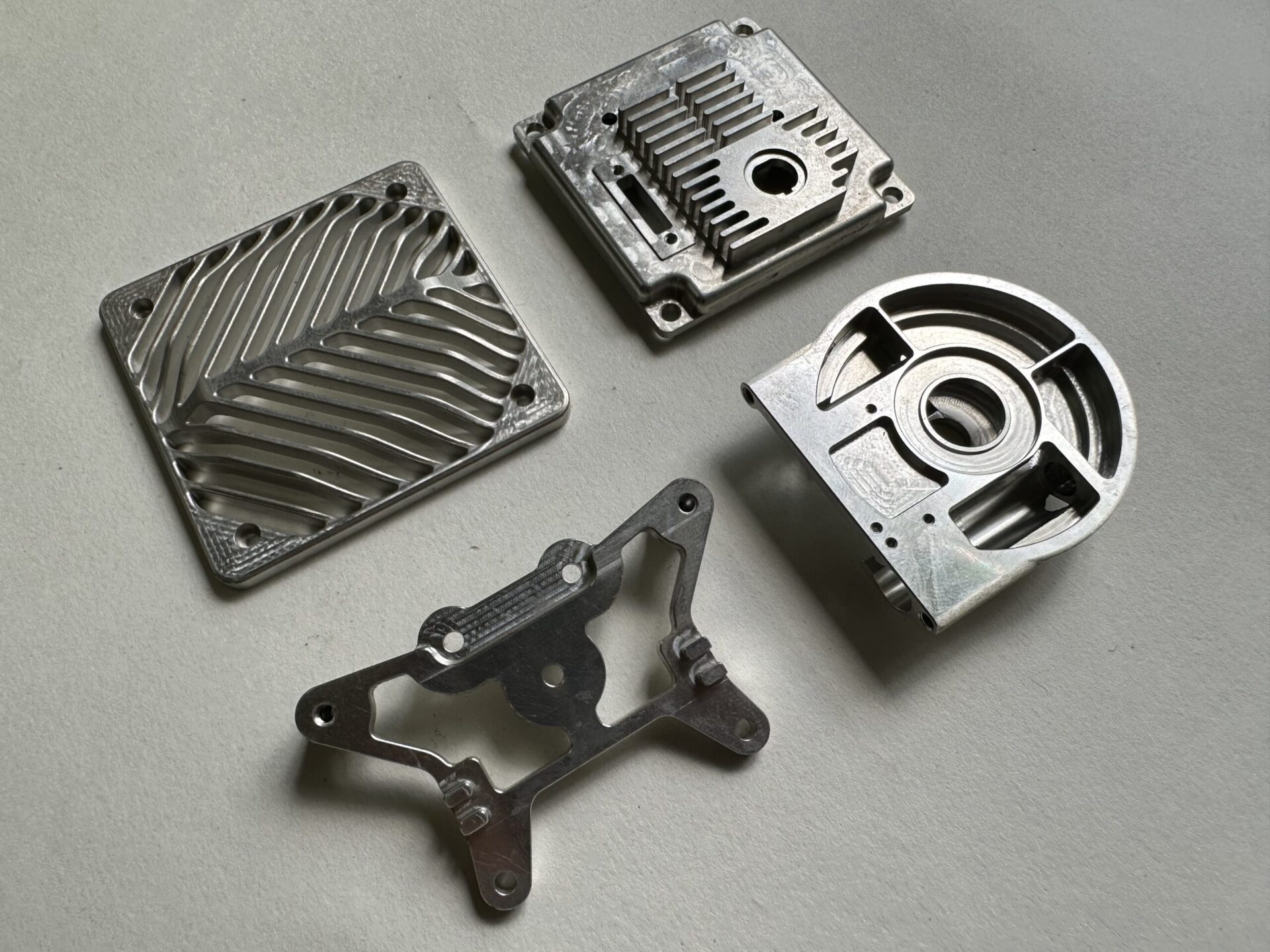

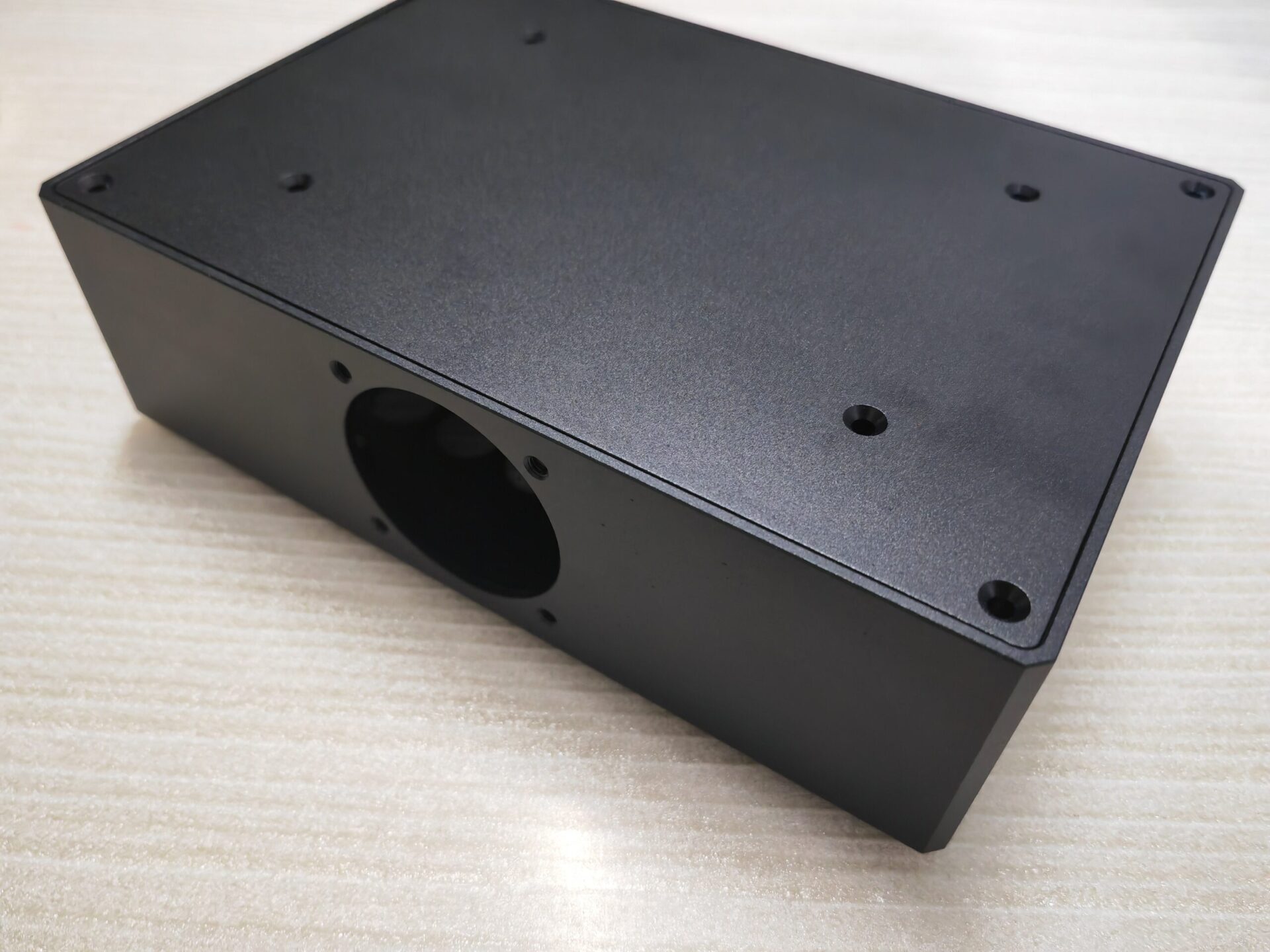

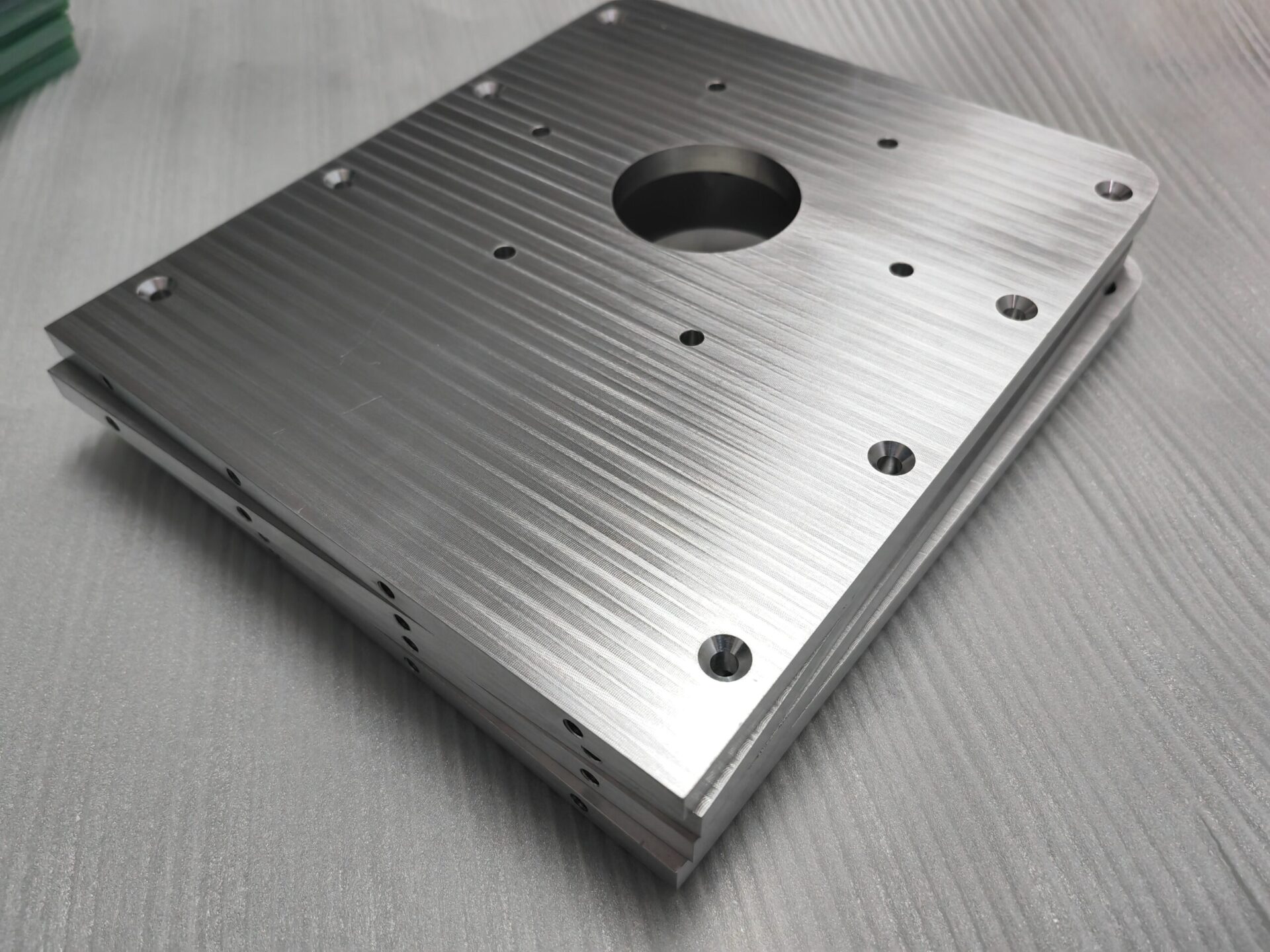

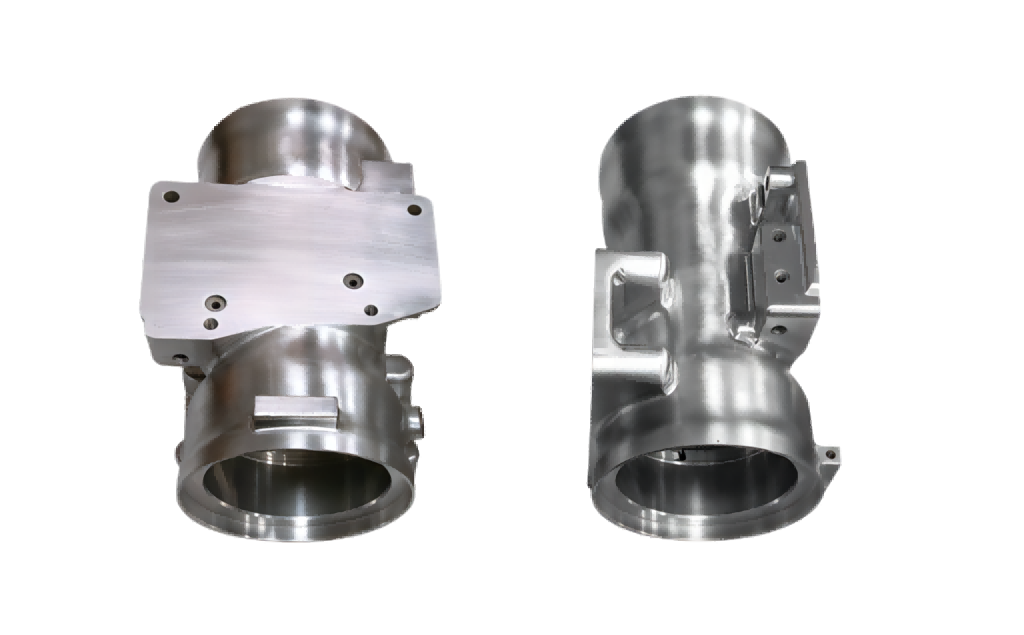

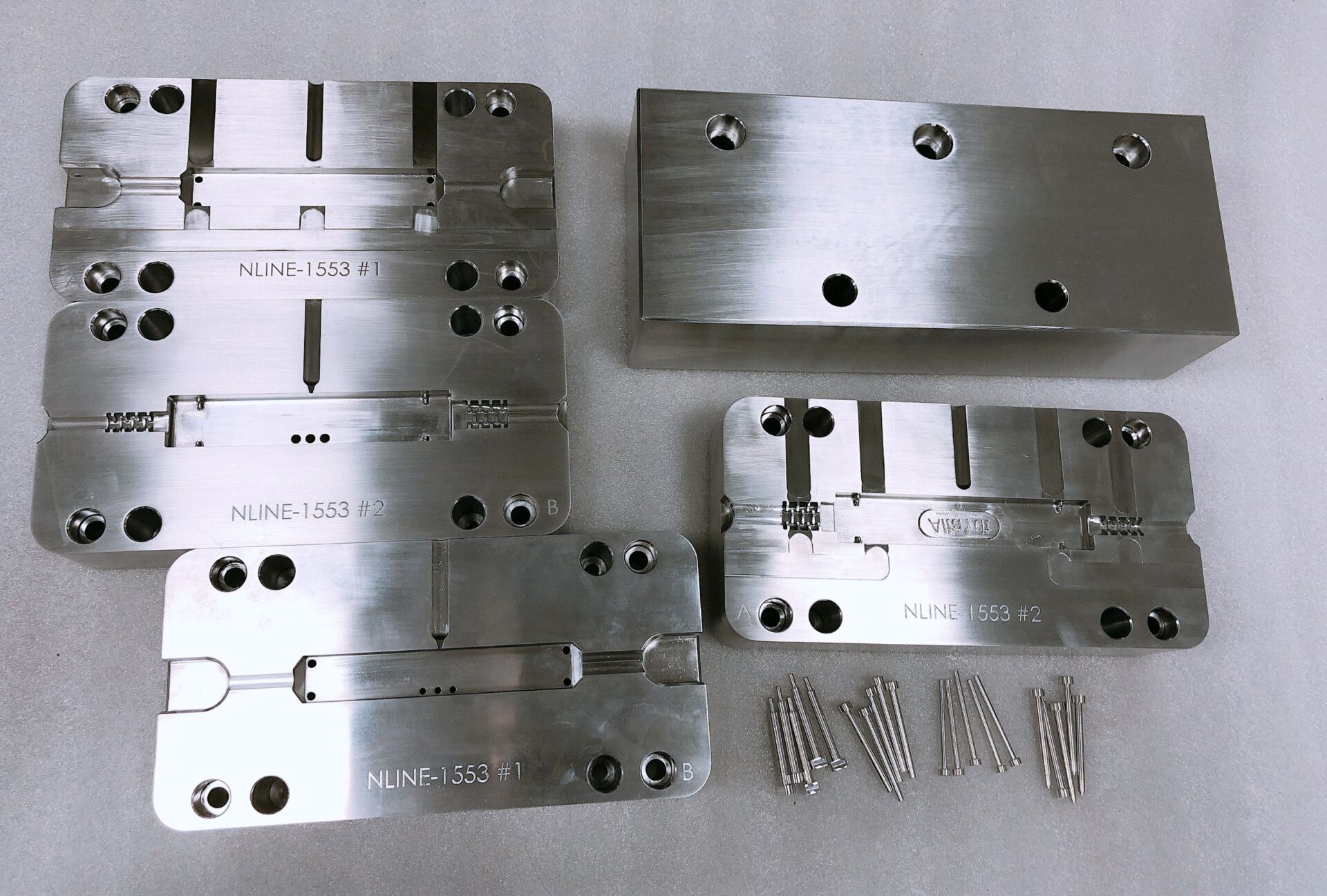

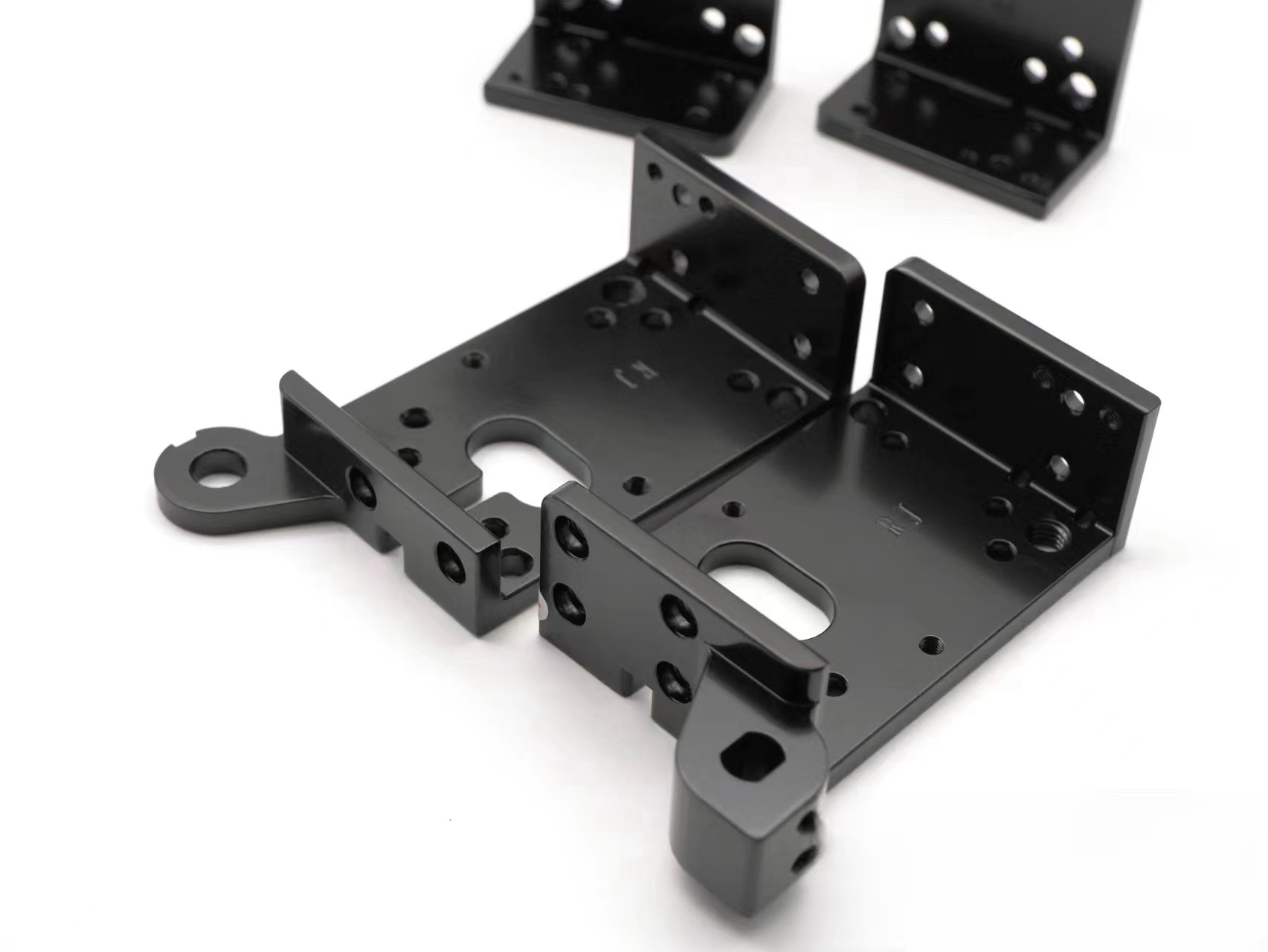

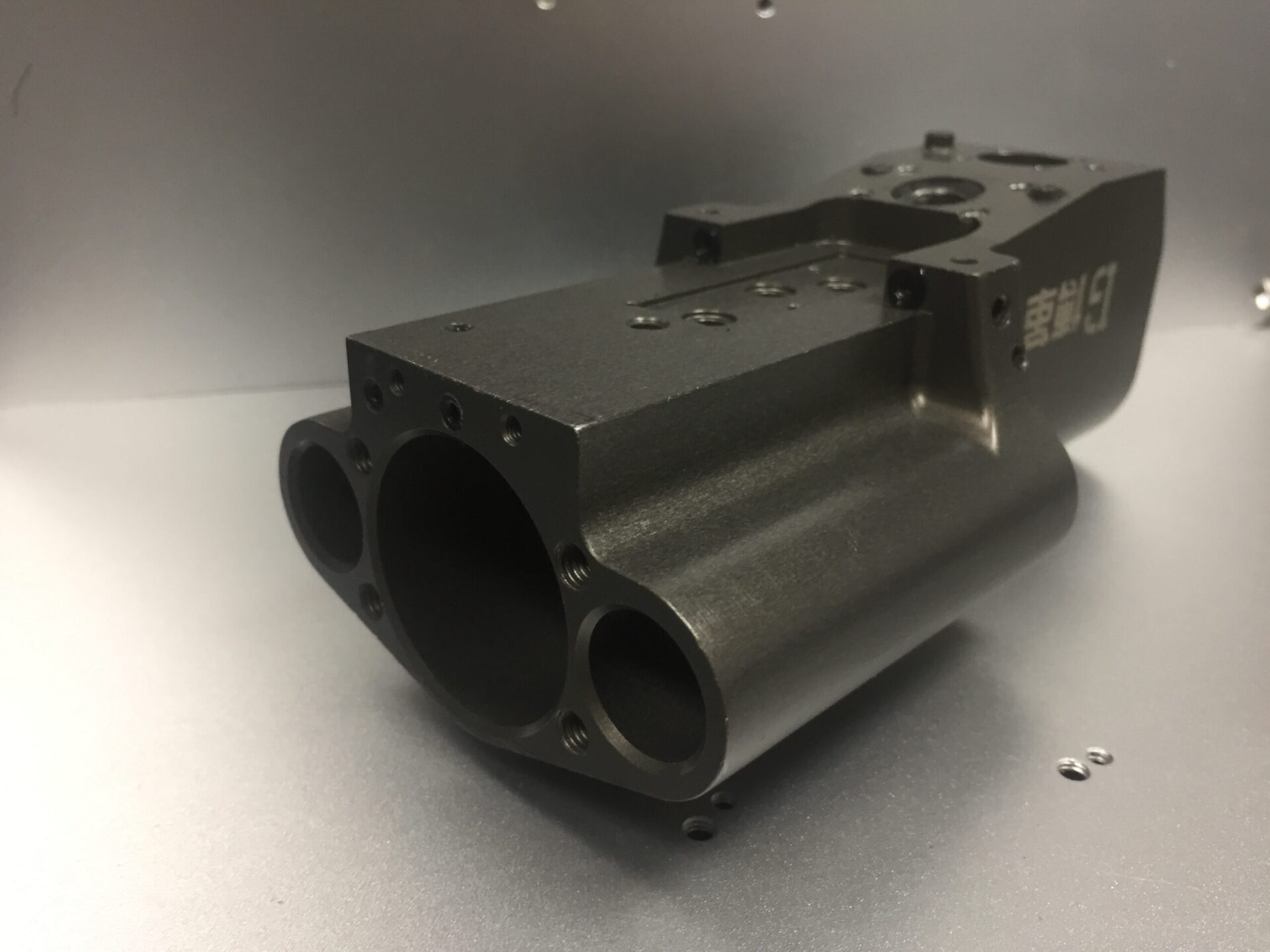

Gallery Of Our CNC Machining Parts

Surface Finishes For CNC Machined Parts

As machined (Ra 3.2μm / Ra 126μin)

Smooth machining (Ra 1.6μm / Ra 63μin)

Polishing (Ra 0.8μm / Ra 32μin or better)

Bead Blasting

Tumbled

Bead blasted + Anodizing

type II

Bead blasted + Anodized type III (Hardcoat)

Black Oxide

Powder Coated

Chromate Conversion Coating

Plating

DLC (Diamond-Like Carbon) Coating

We are also able to boast the following:

- ISO 9001:2015 Accreditation

- Full Material Traceability and Certification ( C of C, 3.1 Certification)

- Compliance with: Conflict Materials, H & S, REACH, RoHS, WEEE

- CAD/CAM Facilities

- Assembly and Sub Assembly

- Comprehensive range of calibrated inspection equipment, such as: Thread Gauges, Slip Gauges, Pin Gauges, Micrometers, Bore Micrometers, Height Gauges, CMM, Quadratic measurement and Surface Testing

- Experience in providing PPAP, SAN, FAI

What Is CNC Machining?

Besides our primary CNC machining services, we enhance production with a variety of manual equipment. This includes resources for manufacturing tooling, jigs, and fixtures, as well as for executing processes like sheet metal fabrication and bending. Our capabilities also extend to cutting and sawing tasks.

Low-volume CNC machining services are a useful bridge between rapid prototyping and mass production, ideal for trial orders and market testing. It serves as a practical assessment strategy for upcoming mass production schedules. For this reason, an increasing number of companies choose vacuum casting or CNC machining, expediting product market entry while providing scope for product improvement based on user feedback.

Meeting Every Customer's Needs

-

Comprehensive Manufacturing Services: Tailored Solutions for Unique Requirements

At ProtoTech Machining, we specialize in providing comprehensive manufacturing services, including CNC machining, rapid prototyping, and sheet metal fabrication. Our team utilizes a range of materials from Aluminum to complex plastics, offering tailored solutions to meet unique customer requirements.

-

Adding Value with Premium Manufacturing: Precision Beyond Basics

We strive to add value to your products through our high-quality manufacturing services such as CNC machining, 3D printing, vacuum casting, and swiss turning. Every order is processed with quality and speed, going beyond basic stages to offer advanced services like vacuum casting and low volume 3D printing.

-

Elevating Components to Refined Products: Specialized Secondary Operations

With our broad range of capabilities in secondary operations, we transform cast, forged, or machined components into finished products. This includes services like FDM, SLS, DMLS, and urethane casting, as well as high-quality cleaning, polishing, and special finishing processes.