Medical & Robotics

Prototech Machining stands at the forefront of innovation, delivering precise solutions for the Medical and Robotics industries. Harnessing cutting-edge technology, we ensure unparalleled accuracy and quality in every project.

- Save 30% on average

Revolutionizing Surgical Precision with

ProtoTech Machining

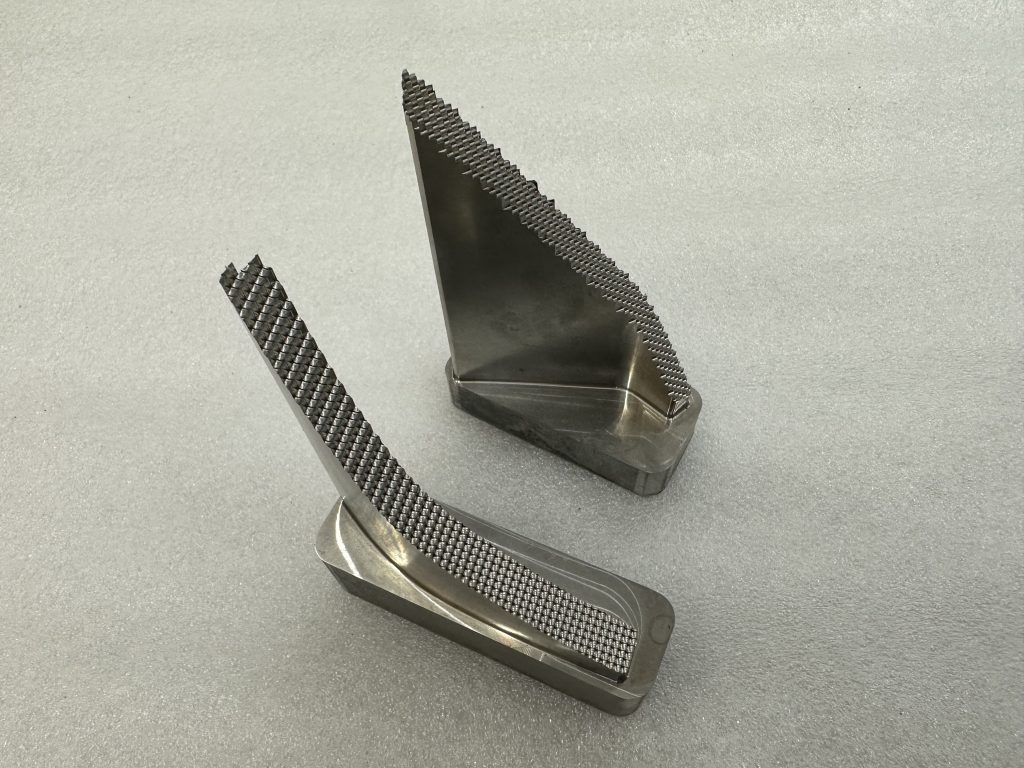

Leveraging medical models developed via rapid prototyping technologies heralds a novel method for surgical planning and simulation. These techniques, which involve CNC machining services and 3D printing technologies like Fused Deposition Modeling (FDM) or Selective Laser Sintering (SLS), enable the reproduction of intricate anatomical objects into tactile 3D models. This provides surgeons with a realistic preview of complex structures pre-surgery.

Why Do Medical Robotic Device Development Companies Use ProtoTech Machining?

Interactive Design Analysis

Make critical design adjustments that save development time and cost with design for manufacturability (DFM) feedback on every quote.

Low-Volume Production

Get low-volume production parts in as fast as 1 day to streamline your supply chain once before and after products are launched to market.

Bridge Tooling Before Production

Leverage affordable bridge tooling for design and market validation before capital investment in tools.

Medical Materials

Choose from high-temperature plastics, medical-grade silicone rubber, and 3D-printed micro-resolution and microfluidic parts, among hundreds of other plastic, metal, and elastomeric materials.

Technology Agnostic

Multiple manufacturing technologies across four services mean your parts are paired with the right equipment and process regardless your project needs.

Rapid Prototyping

ProtoTech Machining in production-grade materials for functional and regulatory testing, or 3D print models and organ scans to preview before medical procedures.

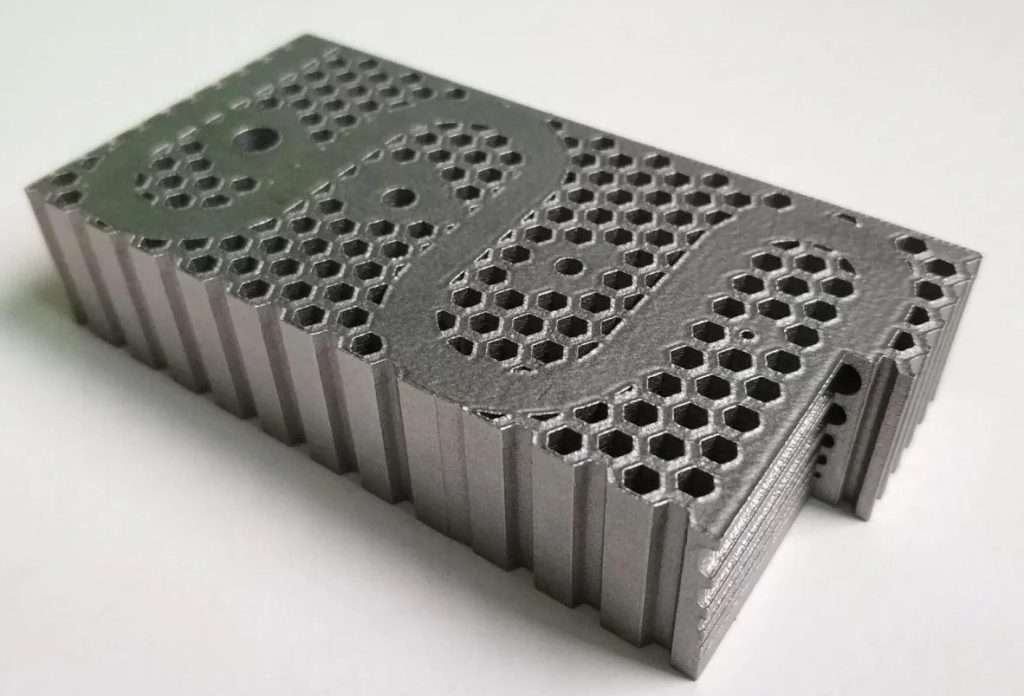

3D Printing Drives Innovation in the Medical Industry

CNC Machining for Medical Parts (Titanium)

What Materials Work Best for Medical Applications?

-

High-temp Plastics

PEEK and PEI (Ultem) offer high-temperature resistance, creep resistance, and are suited for applications that require sterilization.

-

Medical-grade Silicone Rubber.

Dow Corning’s QP1-250 has excellent thermal, chemical, and electrical resistance. It’s also bio-compatible so can be used in applications that require skin contact.

-

Carbon RPU and FPU.

Carbon DLS uses rigid and semi-rigid polyurethane materials to build functional parts ideal for late-stage prototyping or end-use devices.

-

Microfluidics.

Watershed (ABS-like) and Accura 60 (PC-like) are clear materials can be used for microfluidic parts and transparent components like lenses and housings.

-

Medical Alloys.

Between machined and 3D-printed metals along with sheet metal, there are more than 20 metal material options available for medical components, instrumentation, and other applications. Metals like titanium and Inconel have attributes like temperature resistance while various stainless steel materials brings corrosion resistance and strength.

Common Uses of CNC Machined Medical Components

Our precision CNC machined parts find their way into a myriad of healthcare applications, ensuring reliability and excellence. Here’s a glimpse of the diverse range of components we produce:

Diagnostic & Imaging Equipment:

- X-Ray equipment

- MRI devices

- Medical monitor instruments

- Medical diagnosis equipment

- Medical imaging components

- Optics for medical instruments

Treatment & Surgical Devices:

- Ventilators

- Orthopedic implants

- Prosthetic components

- Implantable prototypes

- UV sanitation components

- Medical treatment devices

Testing & Analysis Instruments:

- Cartridges

- Medical testing devices

- Biomedical sensors

- Microfluidic devices

- Anatomical models

- Drug delivery device components

Support & Miscellaneous Components:

- Medical carts

- Medical device motor housing

- Ultrasonic equipment

- Physiotherapy apparatuses

- Medical device enclosures and housings