Telecommunication

At ProtoTech Machining, we pride ourselves on possessing the necessary expertise and cutting-edge equipment to produce precision machined parts and products of superior quality.

- Save 30% on average

CNC Machining in the Communication Industry

CNC machining is a crucial aspect of the communication industry. Utilizing ‘computer numerical control,’ this system employs computers to control and maneuver machines. While commonly used for metal machining, CNC milling cutters can manufacture products across various industries. The versatility of using multiple metals allows engineers to leverage CNC machining for the precise fabrication of communication equipment with complex designs.

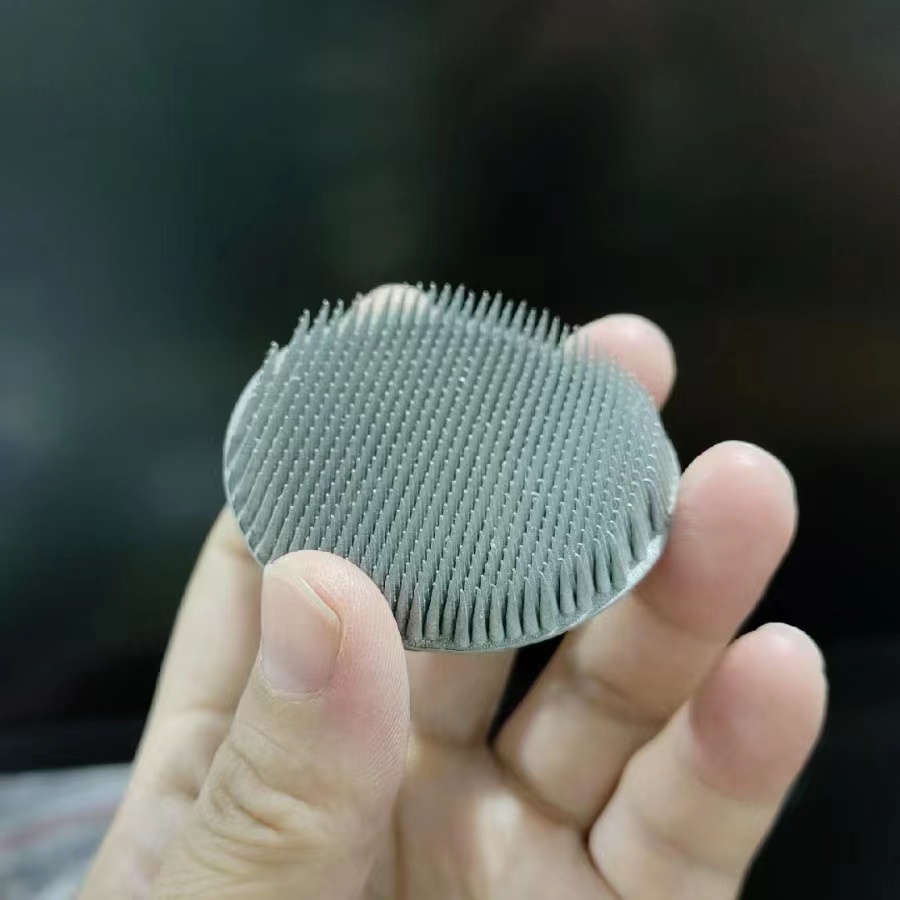

Our Customized CNC Parts Products

Our ProtoTech Machining center excels in machining steel, aluminum, brass, carbon steel, and other special materials. We offer a range of customized finishing services, including full anodizing, carbon black, hard coating for aluminum custom mechanical parts, and galvanizing for steel and iron materials.

Our team provides a comprehensive array of machining services, guided by your expert engineers from conception to implementation, ensuring the seamless execution of your unique project. Beyond traditional milling, drilling, turning, and sawing functions, we deploy sophisticated equipment for special grinding and part marking processes essential for modern applications. If needed, our Certified Partners can deliver heat treatment, welding, electroplating, and painting services before the final stages of inspection, assembly, and packaging. This comprehensive service package ensures cost certainty for our customers and unparalleled quality control against our competitors.

Horizontal and Vertical CNC Machining Centers

ProtoTech Machining offers a diverse range of CNC machining options tailored to the unique requirements of the communications industry. Our projects vary in terms of customized part shapes and production quantities, demanding different approaches. With both horizontal and vertical CNC milling centers at our disposal, we ensure versatility to meet the specific needs of the communication and telecommunication sectors. Our arsenal includes 32 CNC milling centers, featuring six distinct equipment models for maximum flexibility.

Horizontal CNC Milling Center:

- Oriented with a horizontal spindle.

- Ideal for projects involving pockets and surfaces.

- Offers speed and efficiency for tasks requiring substantial material removal.

Vertical CNC Milling Center:

- Spindle is placed vertically.

- Known for simplicity in programming and doesn’t require special fixtures.

- A popular choice for short-term applications.

CNC Machining Service in the Communication Industry

CNC machining stands out as a prime method for ensuring the accurate manufacturing of telecommunication equipment. Leveraging computer technology allows for the design and production of complex specialized parts. CNC machinists employ innovative processing technologies to tackle even the most intricate components.

CNC milling, with its precise computer-controlled production, supports the innovative design of precision products. This method excels in shaping parts from high-strength materials, including stainless steel, steel, brass, and aluminum. Moreover, CNC production is highly efficient, enabling the rapid fulfillment of large orders.

As the communication and telecommunication industry advances, the components required also evolve. The ongoing shift from 4G to 5G technology in the mobile industry demands complex prototypes. CNC-manufactured communication equipment must stay updated to adapt to current and future technologies.

General CNC Parts and Applications

Our expert team specializes in the production of various medical components, including surgical and dental instruments, anesthesia and treatment components, diagnostic equipment, catheters, mandrels, orthopedic devices, heart implants, and other implantable devices. Additionally, we manufacture customized CNC parts for cable and satellite companies, as well as customers in the optical industry.