SWISS CNC Machining

ProtoTech Machining specializes in precision Swiss CNC Machining, delivering intricately crafted components with unparalleled accuracy and quality.

- Save 30% on average

Swiss Machining

We excel in mid to high-volume production runs. However, a significant aspect of our success lies in our expertise in high mix low volume production and our capability to run and ship blanket releases. We pride ourselves on accommodating various order sizes, and there are no minimum order quantity requirements. Nonetheless, it is essential to understand that the part price is influenced by the production volume, as setup costs cannot be spread across a large number of parts. Please keep this in mind while planning your production needs.

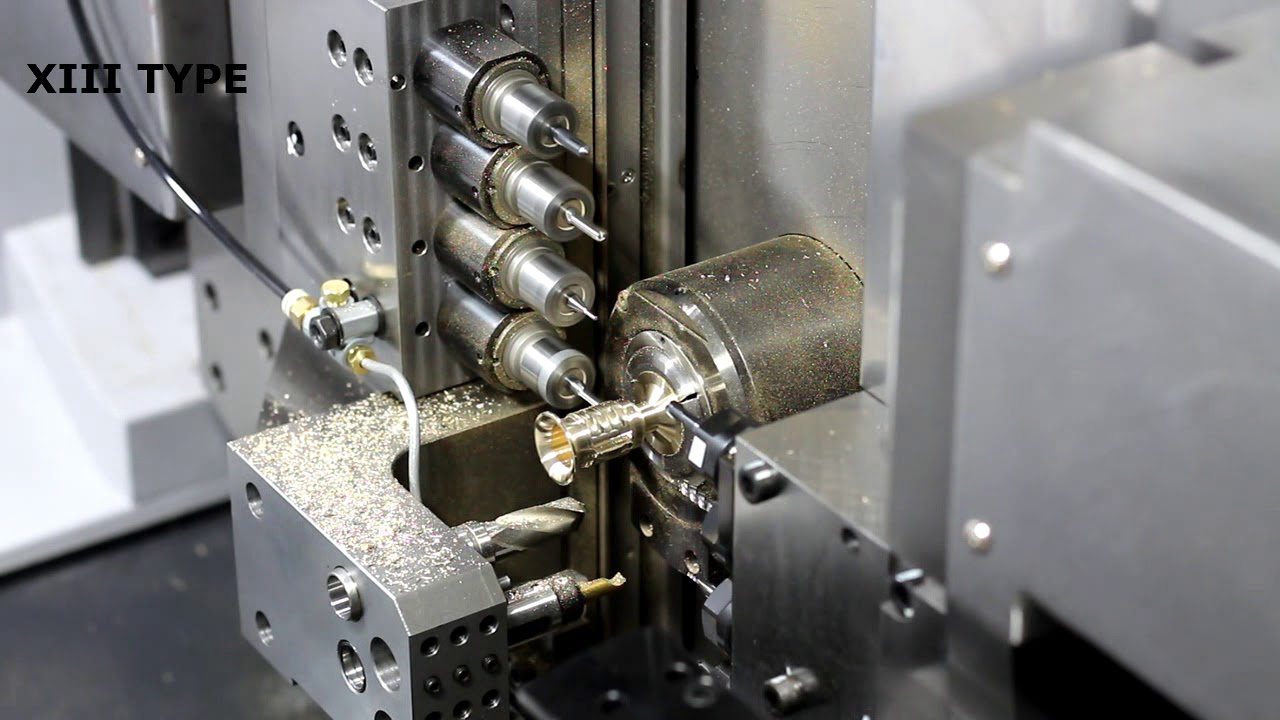

Gallery Of Our CNC Swiss Machined Parts

We machine rapid prototypes and low & large-volume production orders for customers in multiple industries: medical devices, aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, marine and robotics, and many more.

We support high mix, low volume, and high volume production runs.

Swiss Machining Services

Discover precision at ProtoTech Machining, your one-stop-shop for precision machined parts. Our arsenal includes state-of-the-art Swiss-style turning machines, perfect for small diameter products. With the capability to work with various metals, we achieve tolerances as tight as ±.0005″. Equipped with specialized bar feeders, our machines can run ‘lights out,’ handling bar stock up to 1-1/4 inches in diameter and 12 feet long.

Our Registered ISO 9001:2015 Quality Management System guarantees that your small and complex precision parts won’t leave our facilities until they meet or exceed the industry’s toughest standards. Enjoy competitive pricing, personalized customer service, and unparalleled delivery methods.

What Is Swiss CNC Machining?

Swiss CNC machining is a specialized process to machine small, high precision turned parts. A Swiss CNC machine, also referred to as a Swiss automatic lathe, Swiss screw machine, or Swiss-type lathe, was originally designed for the Swiss watchmaking industry. Over the years, the Swiss-style turning machine has been refined to be widely used in various industries for high-volume, high-precision manufacturing – and for good reason.

A Swiss-style lathe is a type of machine that cuts bar stock fed through a guide bushing while the tools keep stationary. The collet is recessed behind the guide bushing so that the bar stock held in it will have better support and will not directly be exposed to the lathe bed and the tooling, so the machine can process the material rapidly and tightly. Also, it plays a great role in decreasing tool deflection and vibration while increasing parts accuracy since the cutting tool can work nearer to the bushing.

How Does A Swiss-type Lathe Work?

A conventional turning machine has a fixed headstock that holds the spinning workpiece when a cutting tool moves across to machine the outer diameter. However, in a Swiss CNC turning center, it employs a sliding headstock that feeds bar stock through a guide bushing in the Z-axis towards the stationary cutting tool.

In the turning operation, clamped onto the chuck or collet in the headstock, the bar stock is located radially and precisely. The headstock moves back and forth along the z-axis, taking the bar stock with it. The turning tools, carried on the gang slide, always engage the bar stock close to the bushing, usually within 1 to 3 mm, thus providing the greatest degree of support and decreasing vibration and tool deflection consequently. And continuous feeding is achieved by the movement of the spindle and the supply of the guide bush.

Custom Machining Processes

- Parting / Cutting

- Form Turning

- Internal / External Threading

- Knurling

- And much more

- Valve Components

- Custom Fittings

- Instrument Components

- Electrical Components

- Lead Free Brass Items